voidstar78

Veteran Member

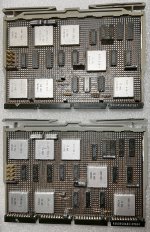

I have two 5110's and one of them has a Display card issue. I know it is the Display card, because I can swap in the Display card from the good 5110 and it boots right up. (and the Bad Display card inserted into the other 5110 causes the same issue as the original 5110 it came from)

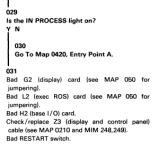

With the "bad" Display card is inserted (in either system), when the system is started the red light at the front comes on, and the Audio buzzer emits a tone (the 5110 added a little speaker behind the CRT, an upgraded feature over the 5100). In the 5110 MAP, I came across this result being consistent with a bad display card. (however, as far as I can tell, the MAP doesn't call out the Audible alert)

I don't think it is the Exec ROS or Base I/O -- because I can take both of those and use them in another 5110 that is functional.

I don't think it is the Z3 cable or RESTART switch, because I can insert cards from the "good" 5110 into this "bad" 5110, and it starts up fine (so all the switches and cables should be fine).

That just leaves "Bad G2"... Which it says to see MAP 050. Well, MAP 050 refers to jumpers that set the Display card for different regions (countries). The type of Display card I have corresponds to the 3rd column below (with the 4 sets of 3 pins), and the jumpers I have are set to EBCDIC (U.S.). I'm not entirely sure what this does, as far as the Display is concerned (load different CRT fonts? change power/Hz requirements?). I could try each variation -- which I plan to try it eventually -- just to eliminate it as being the problem.

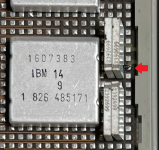

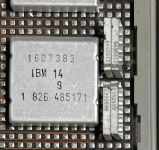

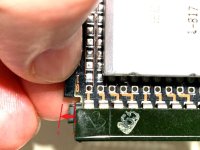

But a specific component on the board got my attention, which I'll explain the next post.

With the "bad" Display card is inserted (in either system), when the system is started the red light at the front comes on, and the Audio buzzer emits a tone (the 5110 added a little speaker behind the CRT, an upgraded feature over the 5100). In the 5110 MAP, I came across this result being consistent with a bad display card. (however, as far as I can tell, the MAP doesn't call out the Audible alert)

I don't think it is the Exec ROS or Base I/O -- because I can take both of those and use them in another 5110 that is functional.

I don't think it is the Z3 cable or RESTART switch, because I can insert cards from the "good" 5110 into this "bad" 5110, and it starts up fine (so all the switches and cables should be fine).

That just leaves "Bad G2"... Which it says to see MAP 050. Well, MAP 050 refers to jumpers that set the Display card for different regions (countries). The type of Display card I have corresponds to the 3rd column below (with the 4 sets of 3 pins), and the jumpers I have are set to EBCDIC (U.S.). I'm not entirely sure what this does, as far as the Display is concerned (load different CRT fonts? change power/Hz requirements?). I could try each variation -- which I plan to try it eventually -- just to eliminate it as being the problem.

But a specific component on the board got my attention, which I'll explain the next post.

Last edited: