Stupid Question...Where is the ram? and how do I remove it? All the chips are soldered onto the board.

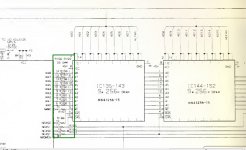

View attachment 32007

Hi there,

POINT 1.. THERE ARE

NO I repeat

NO stupid questions on this forum.!!!!!!!!!!!!!!!! You are amongst like minded friends here. We cannot know everything about everything, and this forum is about helping, asking and providing information and guidance.

Background

What is a processor or memory parity error?

Parity checking is the storage of an extra binary digit (bit) in order to represent the parity (odd or even) of a small amount of computer data (typically one byte) while that data is stored in memory. The parity value calculated from the stored data is then compared to the final parity value. If these two values differ, this indicates a data error, and at least one bit must have been changed due to data corruption.

Within a computer system, electrical or magnetic interference from internal or external causes can cause a single bit of memory to spontaneously flip to the opposite state. This event makes the original data bits invalid and is known as a parity error.

Such memory errors, if undetected, may have undetectable and inconsequential results or may cause permanent corruption of stored data or a machine crash.

There are many causes of memory parity errors, which are classified as either soft parity errors or hard parity errors.

Soft Errors

Most parity errors are caused by electrostatic or magnetic-related environmental conditions.

The majority of single-event errors in memory chips are caused by background radiation (such as neutrons from cosmic rays), electromagnetic interference (EMI), or electrostatic discharge (ESD). These events may randomly change the electrical state of one or more memory cells or may interfere with the circuitry used to read and write memory cells.

Known as soft parity errors, these events are typically transient or random and usually occur once. Soft errors can be minor or severe:

Minor soft errors that can be corrected without component reset are single event upsets (SEUs).

Severe soft errors that require a component or system reset are single event latchups (SELs).

Soft errors are not caused by hardware malfunction; they are transient and infrequent, are mostly likely a SEU, and are caused by an environmental disruption of the memory data.

If you encounter soft parity errors, analyze recent environmental changes that have occurred at the location of the affected system. Common sources of ESD and EMI that may cause soft parity errors include:

Power cables and supplies

Power distribution units

Universal power supplies

Lighting systems

Power generators

Nuclear facilities (radiation)

Solar flares (radiation)

Hard Errors

Other parity errors are caused by a physical malfunction of the memory hardware or by the circuitry used to read and write memory cells.

Hardware manufacturers take extensive measures to prevent and test for hardware defects. However, defects are still possible; for example, if any of the memory cells used to store data bits are malformed, they may be unable to hold a charge or may be more vulnerable to environmental conditions.

Similarly, while the memory itself may be operating normally, any physical or electrical damage to the circuitry used to read and write memory cells may also cause data bits to be changed during transfer, which results in a parity error.

Known as hard parity errors, these events are typically very frequent and repeated and occur whenever the affected memory or circuitry is used. The exact frequency depends on the extent of the malfunction and how frequently the damaged equipment is used.

Remember that hard parity errors are the result of a hardware malfunction and reoccur whenever the affected component is used.

If you encounter hard parity errors, analyze physical changes that have occurred at the location of the affected system. Common sources of hardware malfunction that may lead to hard parity errors include:

Power surges (no ground)

ESD

Overheating or cooling

Incorrect or partial installation

Component incompatibility

Manufacturing defect

that info is from (

http://www.cisco.com/c/en/us/suppor...s-switches/116135-trouble-6500-parity-00.html) Ok it is talking from a routers/switch maker but its principal covers all ram.

So you have a number of possible ways to solve your problem

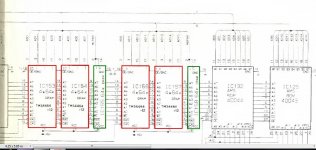

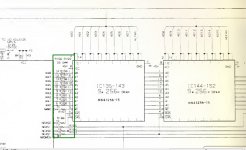

Looking at a Service manual for one of this machine the ram chips are the 2 rows of 9 chips in the bottom left corner of you picture,

ic135 to ic143 being 9 by 256k dram and ic144 to ic152 being the second bank of 9 by 256k dram.

Chips are MN41256-15 (with the 15 means the speed of 150ns) There are other speeds made so if you have to change ram then this is important to note.

Much of the Memory control is handled by a AMS memory Gate array chip IC118 being 40040.

oK So I have highlighted the memory on that clip from the service manual. Look carefully at the pins and solder around them. Also check the green boxed resistors, you may have one of these failed. Use a multimeter on the low ohms range. they are 33ohm value.

If you dont find any visible issue, you can possibly try a measuring the heat of each chip with your finger. if one is very hot compared to the others that likely the problem one.

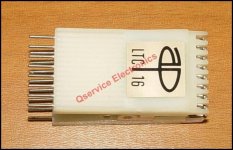

When I have had issues with ram that is soldered in as these appear to be, is rather than try and desolder all, I get a very fine tipped side cutters. ( can let you know model type later) and then with grate care I cut the pins right at side of the ram body. That leaves the legs standing up on the motherboard. Then using a fine tipped temperature controlled soldering iron, and a LOWER melting point fine solder, I solder to the legs a machine tool ic socket. Gold one in preference. Then I can plug in new ram chips.

This is generally easier than trying to desolder the complete chip of out of the motherboard.

In your photo there appears some sort of long 'bracket' maybe between the two rows of 9 ram chips. Not sure as pic is not clear enough. That looks like iif it cannot be removed easily would make soldering piggy back type repair difficult

hope this helps so far

regards

David