Unfortunate, but I also 100% get it.Regarding cases and interface boards, I chatted with Mike a bit when I called to pay for my FDC+.

In a nutshell, he's been in the case business for 10 years now and it's a hobby. It's time to get out of the case business. As someone who's made a hobby into work before, that resonates with me, and I 100% get it.

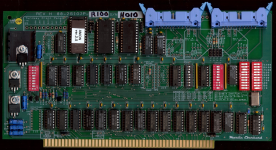

He did say interface board sets should still be available. Also, he thinks he has one dress panel left, along with the bracket to mount it in a case.

-Kevin

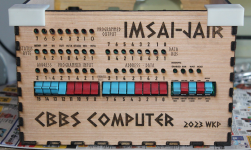

This would seem to mark the end of the Altair 8800c run. Walt's work on designing a wooden box replacement for the 8800c cabinet may fill the gap, but it is far from the "look and feel" of the real thing the 8800c had going for it.