So I got this Sony PC monitor from 1992 that didn't work when I picked it up. I went ahead and tested all the caps and replaced anything bad. There was a absolute ton of caps that had gone high ESR (we are talking 300kOhms high) and there is one board in particular, the DA board, that used surface mount caps which had leaked all over the place.

On the DA board, I removed all the caps and clean it thoroughly with white vinegar and let it sit until it stopped foaming. I cleaned that off and then soaked it with 99% IPA and dried it off with compressed air and let it sit for days to make sure it was dry. The DA board is almost all surface mount, and there are no transformers or anything that might get messed up by being wet. I sprayed all the pots with deoxit and fiddled them a bit to make sure they didn't harbor salts or crust from the whole process.

I also inspected the DA board under a microscope and tested continuity on any areas that seemed more corroded. There didn't appear to be any such issues, and the traces didn't seem to be broken, only exposed in some areas. I suppose it's possible that something under an IC is bad, or a via got damaged because it's a multi-layered board with components on the back side. There is absolutely no apparent damage to the back side.

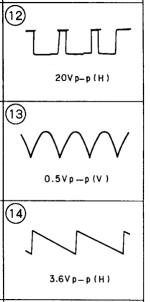

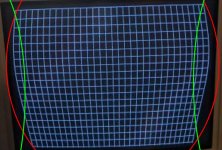

When I got everything back together, I turned on and I got HV, but the image was vertically collapsed. It's only a few pixels high, but it's there enough that I can actually make out the colors in the line and it reflects what should be seen on the screen. For example, I can see where the Windows logo starts and stops on boot, and I can see the proper colors change on the raster horizontally (for example a SMPTE bar image will reflect the bars color across the screen). I can also successfully shift the image horizontally with the screen controls.

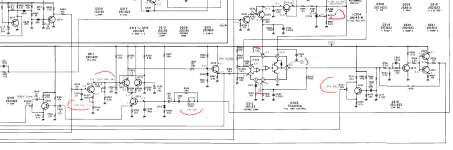

My first thought was that the bad caps on the D board might have blown the Vertical Output IC before I got it, as I have run into that issue a number of times. I bought a handful of the ICs pretty cheaply, but replacing it didn't help or apparently change anything. I thought maybe the replacement could be bad, but a thorough check of the original IC revealed no shorts on the IC, and diode tests between pins seem to make sense for a working IC. I don't believe the original IC was bad at all. I suppose it's still not impossible, but I think it's okay. Anytime this has happened to me in the past, the IC had shorts or low resistance between GND and Vcc or some other pin(s).

So I'm kind of lost here just checking random things. It's extremely difficult to test voltages on this monitor because the portion of the case that holds the CRT is extremely thin and can't be supported by it's structure alone. The only way I could get it to stand up and make adjustments on the inside was to prop it up leaning forward on a towel and balance it that way. Doing this it's not possible to access the bottom of the PCB to take readings. So I disassembled the chassis again and I'm just looking more closely at the DA board in hopes that I can find a culprit.

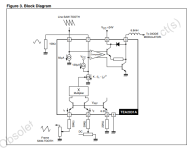

There are a number of small ICs on the DA board that handle all the V and H stuff, and choosing the resolution, I assume based on the frequency of the incoming signal.

Can someone help me to identify which components or areas can cause this condition? Again this is:

-General Vertical Collapse

-There are still a couple of pixels present, enough to match what you are displaying to those few lines as the input changes

-Horizontal seems to be okay in that it spans the whole screen and it is movable with controls

-High Voltage appears to be present as I'm getting the whine and the static on the screen

-Area around the Vertical output IC on the PCB is dark from heat, but none of the component are visually burned or bad and testing a couple so far they looked perfect.

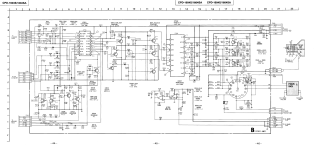

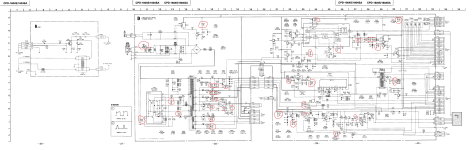

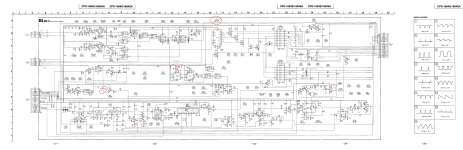

Here is a link to the three pages of the schematic on imgur. I didn't want to put them in-line as they are 11x17 size and would be too big here. If you open the image links and then view them in another tab, you can expand them to see details.

D board:

DA board:

Neck board:

TIA

On the DA board, I removed all the caps and clean it thoroughly with white vinegar and let it sit until it stopped foaming. I cleaned that off and then soaked it with 99% IPA and dried it off with compressed air and let it sit for days to make sure it was dry. The DA board is almost all surface mount, and there are no transformers or anything that might get messed up by being wet. I sprayed all the pots with deoxit and fiddled them a bit to make sure they didn't harbor salts or crust from the whole process.

I also inspected the DA board under a microscope and tested continuity on any areas that seemed more corroded. There didn't appear to be any such issues, and the traces didn't seem to be broken, only exposed in some areas. I suppose it's possible that something under an IC is bad, or a via got damaged because it's a multi-layered board with components on the back side. There is absolutely no apparent damage to the back side.

When I got everything back together, I turned on and I got HV, but the image was vertically collapsed. It's only a few pixels high, but it's there enough that I can actually make out the colors in the line and it reflects what should be seen on the screen. For example, I can see where the Windows logo starts and stops on boot, and I can see the proper colors change on the raster horizontally (for example a SMPTE bar image will reflect the bars color across the screen). I can also successfully shift the image horizontally with the screen controls.

My first thought was that the bad caps on the D board might have blown the Vertical Output IC before I got it, as I have run into that issue a number of times. I bought a handful of the ICs pretty cheaply, but replacing it didn't help or apparently change anything. I thought maybe the replacement could be bad, but a thorough check of the original IC revealed no shorts on the IC, and diode tests between pins seem to make sense for a working IC. I don't believe the original IC was bad at all. I suppose it's still not impossible, but I think it's okay. Anytime this has happened to me in the past, the IC had shorts or low resistance between GND and Vcc or some other pin(s).

So I'm kind of lost here just checking random things. It's extremely difficult to test voltages on this monitor because the portion of the case that holds the CRT is extremely thin and can't be supported by it's structure alone. The only way I could get it to stand up and make adjustments on the inside was to prop it up leaning forward on a towel and balance it that way. Doing this it's not possible to access the bottom of the PCB to take readings. So I disassembled the chassis again and I'm just looking more closely at the DA board in hopes that I can find a culprit.

There are a number of small ICs on the DA board that handle all the V and H stuff, and choosing the resolution, I assume based on the frequency of the incoming signal.

Can someone help me to identify which components or areas can cause this condition? Again this is:

-General Vertical Collapse

-There are still a couple of pixels present, enough to match what you are displaying to those few lines as the input changes

-Horizontal seems to be okay in that it spans the whole screen and it is movable with controls

-High Voltage appears to be present as I'm getting the whine and the static on the screen

-Area around the Vertical output IC on the PCB is dark from heat, but none of the component are visually burned or bad and testing a couple so far they looked perfect.

Here is a link to the three pages of the schematic on imgur. I didn't want to put them in-line as they are 11x17 size and would be too big here. If you open the image links and then view them in another tab, you can expand them to see details.

D board:

DA board:

Neck board:

TIA

Last edited: