Thing have gone from bad to worse. Now I'm barely getting any image on the raster at all, and there is an area that's got the wrong voltages going on. I've been doing the best I can, but I could really use a hand.

There are two main areas that seem to an obvious problem, and they are connected to each other.

-IC604 has a single bad voltage on the input side; Pin 1 is supposed to be 6.5V, but it is zero volts.

Pin 1 appears to be fed by the 12V rail, through a network of resistors and diodes, and something is obviously bringing it down, but I can't figure out what. IC250 and IC302 are fed by the logic of the network coming from IC604, and I can see there is some obvious issues with them that seem consistent to both ICs. Pin 10 on both ICs appears to be very close to the voltage level of Pin 9, which is connected internally to the collector of their diode networks.

I removed IC205 and IC302 from the board and tested them, and they test identically to a new part on diode test setting of a multimeter.

This is my first time looking at diode networks, so I'm not really sure what should or shouldn't be happening with all of these voltages. It's getting overwhelming.

I have replacement ICs for the diode networks that I can try if it looks like a good idea.

-The other area with an obvious problem is Q317, which is getting fed the erroneous 16.5V on it's collector and emitter, which should be 0.6V each. The base is supposed to be 1.2V and it's closer to 20V. The base is connected to emitter through a diode, so I guess it makes sense that it would be a higher voltage since the C and E are also higher. I don't really understand how this diode is suppose to be employed here though.

I checked the voltages on the other ICs and they basically all look right other than the Pin Amp IC (IC303) which still has bad voltage on Pin2, and Pin 7. It seems pretty likely that the issue is just the bad voltage on Pin 2. Pin 2 is fed by the area of the circuit I'm seeing the bad voltages on. Specifically by Q255, which connects to the Vertical controls stuff. If I mess with the Vert Position, it varies the voltage on Pin2 of IC303

I am struggling with where to focus on here. A point in the right direction would be most appreciative.

This is my erroneous voltages:

This is D609 that feeds Q615 and goes to the base of Q613:

This is logic table for IC604, showing that the bad voltage on Pin 1 makes sense with it's output logic.

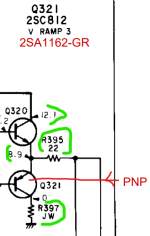

This is what IC250 and IC302 look inside:

Thanks in advance for any help.