Hugo Holden

Veteran Member

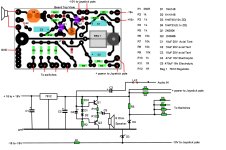

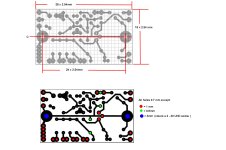

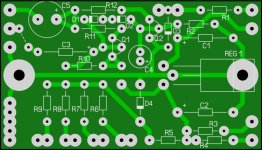

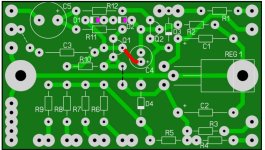

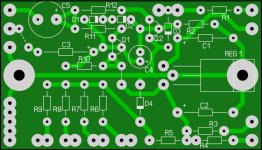

I built a home made proto pcb . (In lieu of plated through holes on a proper pcb where wires pass into a pcb on these home made ones I use 1.5mm brass eyelets)

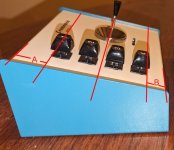

I will test it out today. I want to run it up with an actual OP amp driving the the audio system, rather than a signal generator, just to make sure everything is 100% ok.

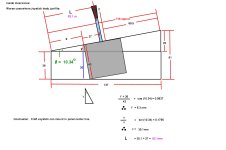

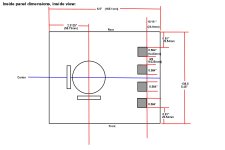

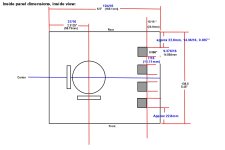

There is plenty pf room for it on the rear of the housing, the inside dimension of that housing there is about 59mm tall and the pcb there is about 41mm.

I will test it out today. I want to run it up with an actual OP amp driving the the audio system, rather than a signal generator, just to make sure everything is 100% ok.

There is plenty pf room for it on the rear of the housing, the inside dimension of that housing there is about 59mm tall and the pcb there is about 41mm.