I just got mine back from JLCPCB and the silkscreen got removed from the copper. Strange, lol.

Well that's annoying! What did the preview show? Did you use the gerber github/zip that Angsar linked to and follow the readme?

| VCF West | Aug 01 - 02 2025, | CHM, Mountain View, CA |

| VCF Midwest | Sep 13 - 14 2025, | Schaumburg, IL |

| VCF Montreal | Jan 24 - 25, 2026, | RMC Saint Jean, Montreal, Canada |

| VCF SoCal | Feb 14 - 15, 2026, | Hotel Fera, Orange CA |

| VCF Southwest | May 29 - 31, 2026, | Westin Dallas Fort Worth Airport |

| VCF Southeast | June, 2026 | Atlanta, GA |

I just got mine back from JLCPCB and the silkscreen got removed from the copper. Strange, lol.

Yup used the provided gerbers and README and the silkscreen on the copper in the gerber viewer/preview image.Well that's annoying! What did the preview show? Did you use the gerber github/zip that Angsar linked to and follow the readme?

Here is the preview of my order and the order settings. Nothing in the copper was printed on the received board.

My experience with JLC ist that the preview is just a preview. They don't feel bound to it in terms of that the final product really looks the same. In fact preview and what the PCB workbench does obviously differ in some aspects. I guess they have included that somewhere in their general terms.

Technically, JLC is capable printing also on bare copper. But it is not finally controlled by the Gerbers. You have to tell them explicitely that you want the silk screen printing NOT being masked off by the openings of the solder mask. And you have to talk to one of their engineers, and to show them a picture of the original Dazzler so they understand what you mean. It is not necessarily sufficient to just talk with sales or support. That at least is my experience.

And JLC has not the option to gold plate the connector fingers only (as it is done by most S100 boards, including the Dazzler). If you chose that option, the whole board changes to ENIG.

If you like to be even more accurate, the vias for circuit board #1 are tented (=covered with solder mask), and untented for circuit board #2. JLC has an option to select for this in the self configuration (called via covering), but again you have to make sure with the JLC engineers that this option also is really being executed.

I have sum up all the hints in the README included with the Gerbers. I am planning to do another batch for those located in Europe, but I am still looking for a manufacturer who can gold plate the fingers only.

I would assume that the README included in the Gerbers is the natural place to put the hints there, but there is no reason not to also publish it at other placesHi,

Once you have a good setup at JLCPCB for the boards, maybe you can make the order "public" so other people can know they're getting everything correct? https://oshwlab.com/ ... Just an idea to make it easier for others.

.

Very good findings, thanks! Yes, with a closer look the E&S Picture System indeed works out as a vector graphics system with refresh buffer for the line drawing commands, not for the pixels.I'm not sure why you're calling this a framebuffer based system? If you read the specs this is pretty clearly a vector based display engine. The "Functional Specifications" describe display rates in terms of the maximum number of line segments or characters it can stroke at 30FPS and the refresh buffer is 8K of 36 bit words containing coordinate data, not pixels. It appears to be a descendant of the Line Drawing System-1 from 1969. Also, Here's the a manual on Bitsavers that definitely makes it clear this is a vector system...

Very good findings, thanks! Yes, with a closer look the E&S Picture System indeed works out as a vector graphics system with refresh buffer for the line drawing commands, not for the pixels.

The Xerox Alto (1973) for sure had a frame buffer based graphics system, too. Maybe related to the work on the Superpaint system also done at Xerox Parc.

I agree that the Dazzler is not easy to program due to its 0.5K block oriented design and the weird pixel arrangement in each buffer location for monochrome mode. The Matrox on the other side did the pixel-to-bit-position conversion in hardware, which speeds things up significantly. However, the Matrox only supports a single graphics mode, and offering the same conversion for both nibble and 4x4 mode for the Dazzler probably would have required a third circuit board.

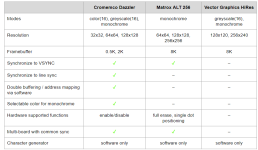

When I try to compare the three S100 boards I am aware of, it works out to something like this

View attachment 1288514

Doesn't look bad for the Dazzler, overall.

Addendum to the above: following the reference to the IEEE publication on the Superpaint, there is also a history arcticle included in the same issue with some reference to frame buffers as essential part of a "painting system" (see for the article here). Citation: "In 1975, a full-color frame buffer for television resolution frames occupied three large racks of equipment, about three kitchen refrigerators in size, and cost over a million 1999 dollars. Today, this same device is called a graphics card and fits in one small slot in a personal computer. It costs on the order of ten dollars, and every PC has one."

When I try to compare the three S100 boards I am aware of, it works out to something like this

I agree that the Dazzler is not easy to program due to its 0.5K block oriented design and the weird pixel arrangement in each buffer location for monochrome mode.

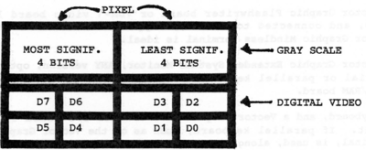

The Vector Graphics HiRes board uses a quite similar dot assigment in one byte (same scheme for greyscale, and also covering four bits horizontally and two bits vertically for monochrome, but with reverse order):I guess what makes the mono Dazzler particularly weird is it's the only system I can think of off the top of my head in which the "semigraphics" character it produced had more pixels horizontally than vertically. IE, the 128 pixel wide mono resolution of the Dazzler was essentially a 32x64 grid of 4x2 semigraphics characters; a typical "text and graphics at the same time" system would have 2x6 graphics grids (which with 64x16 would give you 128 x 48), and there were systems that could do a "full graphics" mode where they'd ditch the text and use the whole byte to do 2x4. (I believe the latter strategy, selected via attribute bytes, is how the Compucolor 8001 managed to pull off its maximum stated resolution of 160x192; an 80x48 grid of characters cut up into 2x4 graphics blocks.)

The Vector Graphics HiRes board uses a quite similar dot assigment in one byte (same scheme for greyscale, and also covering four bits horizontally and two bits vertically for monochrome, but with reverse order):

View attachment 1288559

Yes, as far as I understand, the Dazzler tries to fetch 16 or 32 bytes (depending whether 0.5K or 2K mode is enabled) in a single bulk transfer via DMA to the shift register memory which operates as a cache, so that maximum time remains for the CPU to gain access in between.I found the manual for this thing, and... wow. Reading it kind of makes my head hurt, the way they define "pixel" as being the area taken by the grayscale pixels even when they're in high-res mode...

I mean, I guess I get why they did it this way; it saves them having to change the rate they scan through memory between the high-res-mono and 16 gray modes; with this setup they can leave it fixed at a constant 64 bytes per line with the same address block repeated every other line... but, ugh.(*)

(* This seems like a decision that makes sense for the Dazzler, because it has a shift register line buffer on it that lets it play back a line of pixels multiple times for the scanlines they cover, but it's a little more baffling for this card since this thing straps directly onto a RAM card and turns it directly into framebuffer memory instead of using an across-the-bus DMA.)

But due to the lack of a cache, it looks like the circuit for the monochrome mode has to grab every pixel byte twice (once for each line). But I need to have a closer look at the schematics.

The new REV D boards work perfectly - this build set fired right up on the first attempt (after adjusting the pots/adj cap). Terrific work guys! I have 2 blank PCB sets left.

View attachment 1287692

Thanks to Hugo, Ansgar, Aron, Dave, Gary and anyone else I may have missed for tackling this project. I built up Rev C and. Rev D board sets after seeing Aron’s setup in action at VCF Midwest in September. Due to scrounging parts for 50 years, I only had to order a few oddball resistors, the 22uh inductors, 3 500ohm pots and 2 of the TMS3417. I am only had 1 of the 7483 adders but in meantime I am using a couple of 74LS83s to test the boards and they seem to work fine. I will order the proper 7483s this week. After setting up the boards per the manual, I ran the KSCOPE program and it looks fine. One interesting thing in the red color is not as accurate on the Rev D board as the Rev C board. The red is a little more orange than I would like. Probably has something to do with component tolerance but I will find out. I am just happy both sets are working.

I built an IMSAI in 1977 but I always wanted a Dazzer. Thank you all for making this a reality!

Here are a few pics of the builds and the KSCOPE display. The missing chip on the Rev D board is the 7483.