Endersending

Experienced Member

Hello to everyone,

I have an IMSAI 8080 I am currently working on. recently purchased a floppy controller and a serial card from ebay and now that I have them with no documentation I am stuck.

The floppy controller:

This is a TEI inc FDC-2 floppy controller card. I have been looking for a manual or documentation or anything else but my searching is coming up short.

Deramp.com has a picture (which I believe is this actual card, since they both have the pen writing on the left blue cable connector) and also a picture of the schematics which is too low resolution to read. If anyone has any information about this card I would greatly appreciate it.

The card uses a FD1771 controller for the floppy. I would think the design of the board is generic except for jumpers/configuring. To the left of the upper eprom socket, there are some solder points on the board labeled "port" and H, L, B. What is a port to a floppy controller? I think H = high, L = low, B = bit. So you would solder a jumper from B to either H or L depending on what you want the bit set to. The board currently shows the rght most bit jumped low and the rest floating. I think.

There is also another jumper between the blue cable connectors. 2 rows, one marked SK K and SD D. I am thinking the SD D is for single or double density? maybe not.

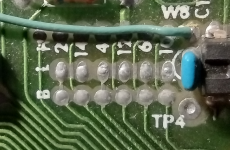

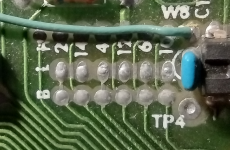

There is also a jumper block above the crystal in the middle of the board. the left of the jumpers say B L H (bit, low, high?) and numbers going across 2, 14, 4, 12, 6, 10. Maybe these are address bits? you can see from the picture below that the jumpers have default settings: 010111

The 2 empty sockets on the board are for EPROMs. when I purchased the board the picture on ebay showed a 2708 EPROM chip in the lower socket with a label on it saying "F000, V1.43". That chip did not come with the board and the seller has no idea where it is.

I assume F000 is the address of the chip, and so I could also assume that I could put a new chip in that socket, I could access it at that address. does this sound correct? I am also thinking that the EPROMs are separate from the floppy controller, in that they do not need each other to function.

This leaves me at the next step of creating a bootable rom image. What would be a good image to start with? I know there are some different monitors people have written over the years and I would have to modify code to match my setup. Like addresses to where the floppy controller lives, and where the serial card is addressed.

Any help, information and insight into how this card operates would be extremely helpful. I also bought a serial card with the same problem of not having documentation or knowledge to use it and I will post that in a different thread.

Thank you for the help. It is awesome to to have resources like this to ask questions.

I have an IMSAI 8080 I am currently working on. recently purchased a floppy controller and a serial card from ebay and now that I have them with no documentation I am stuck.

The floppy controller:

This is a TEI inc FDC-2 floppy controller card. I have been looking for a manual or documentation or anything else but my searching is coming up short.

Deramp.com has a picture (which I believe is this actual card, since they both have the pen writing on the left blue cable connector) and also a picture of the schematics which is too low resolution to read. If anyone has any information about this card I would greatly appreciate it.

The card uses a FD1771 controller for the floppy. I would think the design of the board is generic except for jumpers/configuring. To the left of the upper eprom socket, there are some solder points on the board labeled "port" and H, L, B. What is a port to a floppy controller? I think H = high, L = low, B = bit. So you would solder a jumper from B to either H or L depending on what you want the bit set to. The board currently shows the rght most bit jumped low and the rest floating. I think.

There is also another jumper between the blue cable connectors. 2 rows, one marked SK K and SD D. I am thinking the SD D is for single or double density? maybe not.

There is also a jumper block above the crystal in the middle of the board. the left of the jumpers say B L H (bit, low, high?) and numbers going across 2, 14, 4, 12, 6, 10. Maybe these are address bits? you can see from the picture below that the jumpers have default settings: 010111

The 2 empty sockets on the board are for EPROMs. when I purchased the board the picture on ebay showed a 2708 EPROM chip in the lower socket with a label on it saying "F000, V1.43". That chip did not come with the board and the seller has no idea where it is.

I assume F000 is the address of the chip, and so I could also assume that I could put a new chip in that socket, I could access it at that address. does this sound correct? I am also thinking that the EPROMs are separate from the floppy controller, in that they do not need each other to function.

This leaves me at the next step of creating a bootable rom image. What would be a good image to start with? I know there are some different monitors people have written over the years and I would have to modify code to match my setup. Like addresses to where the floppy controller lives, and where the serial card is addressed.

Any help, information and insight into how this card operates would be extremely helpful. I also bought a serial card with the same problem of not having documentation or knowledge to use it and I will post that in a different thread.

Thank you for the help. It is awesome to to have resources like this to ask questions.