alan8086

Experienced Member

Hi - just wanted to post a process of repair for anyone faced with a similar issue - you must own an ABI ACT-24 chip tester or its rebranded RS Components brother (like mine) for tis to be relevant to you.

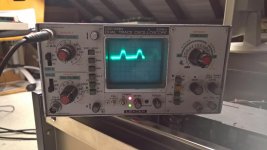

For the 3rd time, I found myself testing all 128 2114 RAM ICs in my IMS 8000 S100 computer

2/3rds through the first board and THIS appears!

First thought - this thing must be fixable - take the lid off, out with the logic board and lets Dremel/wire brush the pins on the 2 BIOS EPROMS! Put it back together and nothing! Unsurprising.

Next - calm down! Re visit the one site on the innerweb that actually has detailed info on this particular chip tester...

http://www.jammarcade.net/abi-ict-24-digital-ic-tester-tech-info/

Half way down the page, this genious has disassembled the BIOS on his unit and actually worked stuff out - as in what the fault codes mean!!! I quote:

Fault 2:

One of the IOÂ’s on PORTB is tied to VCC.

The software sets all of the IO pins on PORTB to logic LOW and reads the states back. If any pins are found to be logic HIGH on PORTB then this will result in FAULT 2.

WHATS A PORTB!!!!???

Ok, next step - further up the page he 'derives a memory map????!! Huh? As follows...

Once I had drawn it out I derived the following memory map

$0000-$3fff – ROM1

$4000-$7fff – ROM2

$8000-$87ff – RAM

8255 (IC1)

$c000 – PORTA

$c001 – PORTB

$c002 – PORTC

$c003 – Control

8255 (IC2)

$c004 – PORTA

$c005 – PORTB

$c006 – PORTC

$c007 – Control

8255 (IC3)

$c008 – PORTA

$c009 – PORTB

$c00a – PORTC

$c00b – Control

8279 (IC8)

$c00c – Data

$c00d – Control

Â….IC1...IC2...IC3 - all 8255s!! I CAN DO THIS!!

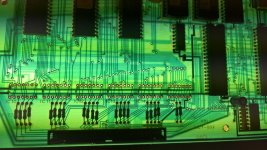

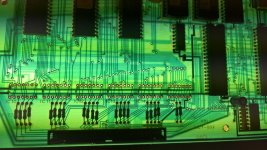

Those are the big PPI chips I can see in front of my face - lets look closer...

...Ok, I can see lots of bus lines going from all those PPI chips to the row of 74LS125 chips below - 'MUST' be something to do with one of those??

'If any pins are found to be logic HIGH on PORTB then this will result in FAULT 2'

My dimwit diagnosis - one of those 74LS125 chips is holding one of those PPI chip pins logic High!

Forget the Logic Probe - lets desolder all 6 of those chips and test them in my End Of The World logic chip tester - the MiniPro TL866A! and YES! It supports the 74LS125!! We can do this!

DeslderingÂ…

TESTING! TESTING! TESTING! and yessssss!! nfire:

nfire: nfire:

nfire: nfire:

nfire:

We have a probable suspect - lets socket the thing!!

Damnaggit - run out of 14 pin sockets!! Lets Make one!

Now we have 6 14 pin sockets where once we had 6 74LS125's

But which is the faulty chip?? THIS one...

Do I have any spare 74LS125?? NOOOOOOOOOOOOO!!!!!!!

5 Now on Order...

https://www.ebay.co.uk/itm/112367499720

Along with 20 14 pin IC sockets:

https://www.ebay.co.uk/itm/223096101340

Stay Tuned For Next Weeks Installment! Will Bobby Die? Will Su-ellen Wake up in the shower and realise 6 weeks of filming was all a dream? WILL THE ABI ICT-24 GET FIXED!!!!!

For the 3rd time, I found myself testing all 128 2114 RAM ICs in my IMS 8000 S100 computer

2/3rds through the first board and THIS appears!

First thought - this thing must be fixable - take the lid off, out with the logic board and lets Dremel/wire brush the pins on the 2 BIOS EPROMS! Put it back together and nothing! Unsurprising.

Next - calm down! Re visit the one site on the innerweb that actually has detailed info on this particular chip tester...

http://www.jammarcade.net/abi-ict-24-digital-ic-tester-tech-info/

Half way down the page, this genious has disassembled the BIOS on his unit and actually worked stuff out - as in what the fault codes mean!!! I quote:

Fault 2:

One of the IOÂ’s on PORTB is tied to VCC.

The software sets all of the IO pins on PORTB to logic LOW and reads the states back. If any pins are found to be logic HIGH on PORTB then this will result in FAULT 2.

WHATS A PORTB!!!!???

Ok, next step - further up the page he 'derives a memory map????!! Huh? As follows...

Once I had drawn it out I derived the following memory map

$0000-$3fff – ROM1

$4000-$7fff – ROM2

$8000-$87ff – RAM

8255 (IC1)

$c000 – PORTA

$c001 – PORTB

$c002 – PORTC

$c003 – Control

8255 (IC2)

$c004 – PORTA

$c005 – PORTB

$c006 – PORTC

$c007 – Control

8255 (IC3)

$c008 – PORTA

$c009 – PORTB

$c00a – PORTC

$c00b – Control

8279 (IC8)

$c00c – Data

$c00d – Control

Â….IC1...IC2...IC3 - all 8255s!! I CAN DO THIS!!

Those are the big PPI chips I can see in front of my face - lets look closer...

...Ok, I can see lots of bus lines going from all those PPI chips to the row of 74LS125 chips below - 'MUST' be something to do with one of those??

'If any pins are found to be logic HIGH on PORTB then this will result in FAULT 2'

My dimwit diagnosis - one of those 74LS125 chips is holding one of those PPI chip pins logic High!

Forget the Logic Probe - lets desolder all 6 of those chips and test them in my End Of The World logic chip tester - the MiniPro TL866A! and YES! It supports the 74LS125!! We can do this!

DeslderingÂ…

TESTING! TESTING! TESTING! and yessssss!!

We have a probable suspect - lets socket the thing!!

Damnaggit - run out of 14 pin sockets!! Lets Make one!

Now we have 6 14 pin sockets where once we had 6 74LS125's

But which is the faulty chip?? THIS one...

Do I have any spare 74LS125?? NOOOOOOOOOOOOO!!!!!!!

5 Now on Order...

https://www.ebay.co.uk/itm/112367499720

Along with 20 14 pin IC sockets:

https://www.ebay.co.uk/itm/223096101340

Stay Tuned For Next Weeks Installment! Will Bobby Die? Will Su-ellen Wake up in the shower and realise 6 weeks of filming was all a dream? WILL THE ABI ICT-24 GET FIXED!!!!!

Attachments

Last edited: