Hi All,

I'm gearing up to take a shot at resurrecting an old 11/15 which I saved from the dumpster about 30 years ago. It has just been sitting on my shelf since then and I'd love some ideas to get me started in the right direction.

At one point it fired up and responded correctly to some front panel toggling. Last time I powered it on it +5V failed to come up and I quickly shut it off. I suspect that the first order of business will be to take a good look at the power supply. I learned to program on an 11/35 but I'm not an electrical engineer so this will be something of an adventure!

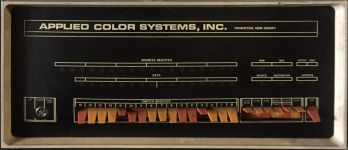

This machine appears to have been an early version of a workstation at Carnegie Mellon. The names on some of the custom boards include founders of Three Rivers Computer (PERQ, which spun out of CMU) so there may be some history there. At least it has a lot of custom boards in it relating to tablet I/O and perhaps early networking? Is that what the Asynchronous Line Interface is? I'm not sure what UMBAWA stands for...

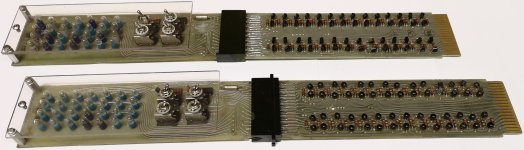

The backplane is almost full:

Any leads on a replacement deposit switch and an easy way to rig up some (real or emulated) disk or tape storage? Suggestions on what my first steps should be?

Thanks!

-Bill

I'm gearing up to take a shot at resurrecting an old 11/15 which I saved from the dumpster about 30 years ago. It has just been sitting on my shelf since then and I'd love some ideas to get me started in the right direction.

At one point it fired up and responded correctly to some front panel toggling. Last time I powered it on it +5V failed to come up and I quickly shut it off. I suspect that the first order of business will be to take a good look at the power supply. I learned to program on an 11/35 but I'm not an electrical engineer so this will be something of an adventure!

This machine appears to have been an early version of a workstation at Carnegie Mellon. The names on some of the custom boards include founders of Three Rivers Computer (PERQ, which spun out of CMU) so there may be some history there. At least it has a lot of custom boards in it relating to tablet I/O and perhaps early networking? Is that what the Asynchronous Line Interface is? I'm not sure what UMBAWA stands for...

The backplane is almost full:

Any leads on a replacement deposit switch and an easy way to rig up some (real or emulated) disk or tape storage? Suggestions on what my first steps should be?

Thanks!

-Bill