Twylo

Experienced Member

This beast just arrived in my garage:

It's a PDP-11/35 with a DSD 440 (RX02 compatible) floppy drive, RK03 drive, and an EECO paper tape punch/reader. It was originally owned by ATARI, but I have no idea what they did with it.

This thing is not what you would call "show room ready". It's been stored in a shed in Washington for well over a decade, and is caked in filth. Until I've taken every single screw out, put every piece through a hot soapy bath, and given everything a visual inspection, I'm not even going to think about applying power to anything. What I'm saying is, it'll be a while before I start debugging it

But I'm excited to have it. I've wanted a blinkenlights PDP-11 forever. Now that I have one, I'm a little scared of the amount of work I've got myself into, here!

3, 2, 1... panic!

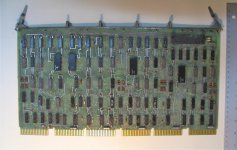

EDIT: I thought I'd edit my post and attach a picture of the card cage, too. The picture isn't the greatest, but it gives an idea. The fluffy stuff is insulation that mice stuffed into the card cage. Shockingly, my first visual inspection doesn't show any major corrosion or damage - just dirt!

It's a PDP-11/35 with a DSD 440 (RX02 compatible) floppy drive, RK03 drive, and an EECO paper tape punch/reader. It was originally owned by ATARI, but I have no idea what they did with it.

This thing is not what you would call "show room ready". It's been stored in a shed in Washington for well over a decade, and is caked in filth. Until I've taken every single screw out, put every piece through a hot soapy bath, and given everything a visual inspection, I'm not even going to think about applying power to anything. What I'm saying is, it'll be a while before I start debugging it

But I'm excited to have it. I've wanted a blinkenlights PDP-11 forever. Now that I have one, I'm a little scared of the amount of work I've got myself into, here!

3, 2, 1... panic!

EDIT: I thought I'd edit my post and attach a picture of the card cage, too. The picture isn't the greatest, but it gives an idea. The fluffy stuff is insulation that mice stuffed into the card cage. Shockingly, my first visual inspection doesn't show any major corrosion or damage - just dirt!

Last edited: