Hugo Holden

Veteran Member

When plastic ages it hardens, and if it is in an application of some force transfer, it can fracture.

I'm posting a plastic repair job here on a small sized item, not because it is part of a computer or disk drive , but to draw attention to three very helpful tools/parts to have in the workshop for fixing broken parts, could be in a computer drive or elsewhere in a computer system.

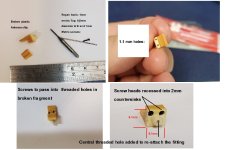

Often, if the fracture surface area is small, in this case it was only about 6mm x 2mm, then just gluing (or plastic solvents) alone would not work, the broken piece of plastic would simply break off again due to the forces when the antenna rod is pushed into the clip, splaying the two arms apart. It requires physical support as well as gluing.

When the parts get small though, the tools and screws have to shrink in size too.

1mm diameter screws can be a very useful size. The drill for a 1mm metric Tap is 0.8mm diameter.

Clearance holes are made for the screws and the holes were countersunk to clear the heads and set the amount the the screw projects into the broken plastic fragment across the fracture interface. The fragment was threaded with the 1mm Tap. Everything for this job is done by hand, with the drills and Taps held in small hand (pin) chucks.

Once the assembly is complete and the parts screw together well, then the screws and fracture interface is coated with 24Hr high strength epoxy resin (like JB weld) and the screws done up and the excess resin wiped away.

This broken part was an Antenna clip on one of my favorite vintage transistor radios.

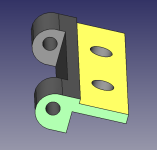

The point being that this very tiny screw & Tap hardware allows the repair of items that would otherwise have to be replaced. In a lot of cases, these days, many broken plastic parts get 3D printed rather than repaired.

I'm posting a plastic repair job here on a small sized item, not because it is part of a computer or disk drive , but to draw attention to three very helpful tools/parts to have in the workshop for fixing broken parts, could be in a computer drive or elsewhere in a computer system.

Often, if the fracture surface area is small, in this case it was only about 6mm x 2mm, then just gluing (or plastic solvents) alone would not work, the broken piece of plastic would simply break off again due to the forces when the antenna rod is pushed into the clip, splaying the two arms apart. It requires physical support as well as gluing.

When the parts get small though, the tools and screws have to shrink in size too.

1mm diameter screws can be a very useful size. The drill for a 1mm metric Tap is 0.8mm diameter.

Clearance holes are made for the screws and the holes were countersunk to clear the heads and set the amount the the screw projects into the broken plastic fragment across the fracture interface. The fragment was threaded with the 1mm Tap. Everything for this job is done by hand, with the drills and Taps held in small hand (pin) chucks.

Once the assembly is complete and the parts screw together well, then the screws and fracture interface is coated with 24Hr high strength epoxy resin (like JB weld) and the screws done up and the excess resin wiped away.

This broken part was an Antenna clip on one of my favorite vintage transistor radios.

The point being that this very tiny screw & Tap hardware allows the repair of items that would otherwise have to be replaced. In a lot of cases, these days, many broken plastic parts get 3D printed rather than repaired.