Are you able to disassemble and remove the cam? If so, repairing it by binding may be a solution. It also doesn't require the crack itself to continue to be structurally sound.

Clean the removed cam with isopropyl alcohol and use a fine thread (I use Kevlar, a cotton-reel size spool is cheap on eBay or at a fishing tackle shop. Get the unwaxed variety).

Put a tiny drop of superglue on the exterior, say 2mm from one end, and attach the end of the thread to this. Then start winding around the cam.

After one turn, pull the thread over the start of the thread to hold it and start applying tension, making sure the crack is being closed.

After another turn, apply more tension and put a tiny drop of superglue across the threads. Try another 5 or 10 turns, superglue. Cut the thread (Kevlar is very tough, use a new Exacto #11 blade or very good scissors) and glue the thread end down then run superglue right around the binding. Do the same for the other end.

I've used this technique many times for things such as cracked RC car wheel hubs and chassis (combined with carbon fibre), telescope mounting repair, hand drill pinion gear repair (the chuck drive pinion was cracked in two pieces), handle repair and so on. It really works and it may well be stronger than the original. A small reel of Kevlar thread will last you many many years for these sorts of repairs, if you can't get it then polyester sewing thread may be used but it's not as strong. Dental floss too, if you can get it unwaxed.

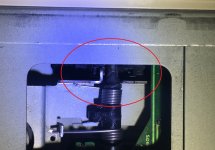

Example of Kevlar thread