I'm trying hard to revive a ST-412 hard drive, coming from an otherwise happy IBM 5160.

I am seeking advice from seasoned retro-heroes or electronic expert as my knowledge about electronic is very basic.

All I know I have learned from Adrian's Digital Basement and other retro Youtubers.

The problem:

The HD doesn't spin up when plugged to power. I can hear a faint click then nothing.

I assumed a stuck platter/heads, but both spindle and step seem to move freely.

I'm doing all the tests with the interface board disconnected from the hard disk sealed inclosure. I assumed it should still be a valid troubleshooting method while avoiding to damage any possible data from the platters.

The voltages on the interface board seem fine, no obvious shortcuts, or blown capacitors, but I have noticed a burning resistor.

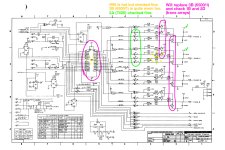

It's R90 from the schematic of the ST-412 model 20110 (attached). It's a resistor by the output of the negative phase A that goes to the spindle. It gets 12V across it.

I have isolated the resistor, and it checks fine off the board. Before the resistor there is a 7406 inverter IC. I isolated it and it seems working fine off the board as well.

Before the 7406 there is the 6500/1. It gets quite warm too. I checked the usual suspects, voltages, reset pin, NMI, CNTR and clock, but all seems OK.

There is no activity on the 4 data channels. They are either high or low. I'm not sure if this is an issue or the CPU is just waiting for a signal (since the HD enclosure is disconnected).

What is next:

I have ordered a couples of 6500/1. I want to try to replace it to see if that's the issue.

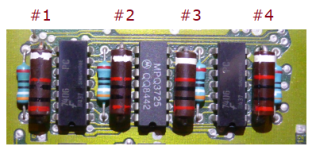

I will also isolate the three transistors array's ICs that seem to interact with the burning resistor from the schematic.

They are two PNP and one NPN that drive the positive and negative phase signals to the spindle.

The questions:

Does this approach make sense? Am I missing something obvious?

I wish to get some expert advice before proceeding, as those ICs are a massive major pain in the floppy to desolder.

Thanks!

I am seeking advice from seasoned retro-heroes or electronic expert as my knowledge about electronic is very basic.

All I know I have learned from Adrian's Digital Basement and other retro Youtubers.

The problem:

The HD doesn't spin up when plugged to power. I can hear a faint click then nothing.

I assumed a stuck platter/heads, but both spindle and step seem to move freely.

I'm doing all the tests with the interface board disconnected from the hard disk sealed inclosure. I assumed it should still be a valid troubleshooting method while avoiding to damage any possible data from the platters.

The voltages on the interface board seem fine, no obvious shortcuts, or blown capacitors, but I have noticed a burning resistor.

It's R90 from the schematic of the ST-412 model 20110 (attached). It's a resistor by the output of the negative phase A that goes to the spindle. It gets 12V across it.

I have isolated the resistor, and it checks fine off the board. Before the resistor there is a 7406 inverter IC. I isolated it and it seems working fine off the board as well.

Before the 7406 there is the 6500/1. It gets quite warm too. I checked the usual suspects, voltages, reset pin, NMI, CNTR and clock, but all seems OK.

There is no activity on the 4 data channels. They are either high or low. I'm not sure if this is an issue or the CPU is just waiting for a signal (since the HD enclosure is disconnected).

What is next:

I have ordered a couples of 6500/1. I want to try to replace it to see if that's the issue.

I will also isolate the three transistors array's ICs that seem to interact with the burning resistor from the schematic.

They are two PNP and one NPN that drive the positive and negative phase signals to the spindle.

The questions:

Does this approach make sense? Am I missing something obvious?

I wish to get some expert advice before proceeding, as those ICs are a massive major pain in the floppy to desolder.

Thanks!