guilfordbob

New Member

- Joined

- Mar 7, 2024

- Messages

- 7

Hi folks,

I'm working on three Superbrain computers for a nearby computer museum. (gratis). One is now working fine, two still need a lot of help, this is about one of them.

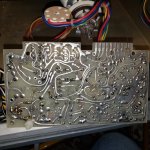

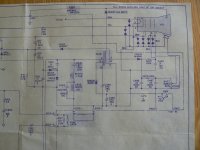

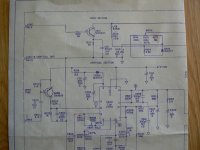

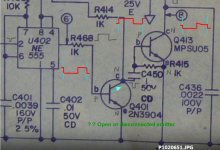

For starters, the monitor board does not seem to match the monitor schematics I've found online. Pix of the boards attached. At first the screen was dark, I replaced a bad tantalum and fuse. Still dark. I replaced the the HOT driver (pre transformer that drives the HOT) because the collector was not pulling down completely to ground. It doesn't look much better on the scope, but at least I now have something on the screen. BTW, the screen has a bad cataract, but I won't bother to work on that if I can't get the video board working.

The HOT has been removed from the board, and a transistor that may or may not be the correct one has been mounted to the chassis with an added diode and cap. Also, the red lead to the pix is not going to the board marked R, but rather to the junction of two resistors that have been put across an existing(?) cap to the left of where the wire came from. However, my favorite 'mod' is the steel file taped to the side of the chassis. (the machine was a donation, maybe it came from a prison!)

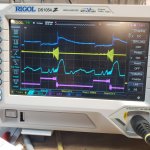

Now I have a raster of sorts. Not terribly bright, and the H-sweep is a mess. You can see some messy text at the top that is telling me to insert a disk in drive A, and below that on the right side of the screen is the CPM 'A>' prompt.

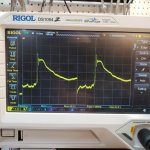

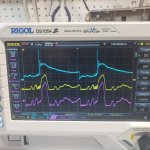

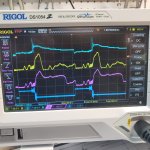

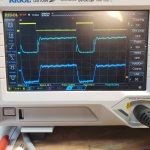

The waveform is the collector of the HOT driver. I think I've rambled long enough. Any insight is appreciated.

I'm working on three Superbrain computers for a nearby computer museum. (gratis). One is now working fine, two still need a lot of help, this is about one of them.

For starters, the monitor board does not seem to match the monitor schematics I've found online. Pix of the boards attached. At first the screen was dark, I replaced a bad tantalum and fuse. Still dark. I replaced the the HOT driver (pre transformer that drives the HOT) because the collector was not pulling down completely to ground. It doesn't look much better on the scope, but at least I now have something on the screen. BTW, the screen has a bad cataract, but I won't bother to work on that if I can't get the video board working.

The HOT has been removed from the board, and a transistor that may or may not be the correct one has been mounted to the chassis with an added diode and cap. Also, the red lead to the pix is not going to the board marked R, but rather to the junction of two resistors that have been put across an existing(?) cap to the left of where the wire came from. However, my favorite 'mod' is the steel file taped to the side of the chassis. (the machine was a donation, maybe it came from a prison!)

Now I have a raster of sorts. Not terribly bright, and the H-sweep is a mess. You can see some messy text at the top that is telling me to insert a disk in drive A, and below that on the right side of the screen is the CPM 'A>' prompt.

The waveform is the collector of the HOT driver. I think I've rambled long enough. Any insight is appreciated.