nikola-wan

Veteran Member

I have had a video issue with my 4054A since my last youtube video with my SVG image of the Back to the Future Delorean Time Machine on Nov 27 2023:

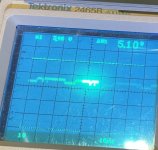

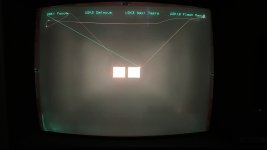

One symptom of the issue is a bright orange spot in the center of the screen after two minutes of inactivity in the program or keyboard as shown in the next picture:

The bright orange spot is two lines above the Diagnostic ROM text.

A second symptom is the series of dots visible under each of the text characters in the middle of the screen - but not visible on the far left and far right sides.

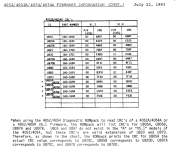

You might notice my Checksum test reporting U845 and U863 CRC Errors - please ignore those messages. When I rechecked the Tektronix CRCs listed in the Diagnostic ROM Pack - U845 and U863 do NOT have CRCs reported on any of the BASIC ROM versions through version 5.1, nor the A-Series version 1.3 and 1.4. I believe I need to remove those two tests as the Diagnostic ROM Pack is bank-switched into the same address 0000-3FFF ROM space as the U845 ROM and therefore cannot actually access the U845 ROM Pack when the CALL "CRC" is being executed.

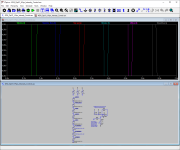

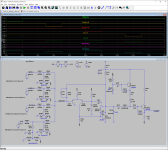

I spent the last two days with my 4054A top cover removed - performing the 4054 service manual calibration test procedure with the calibration programs published in my latest Flash Drive update.

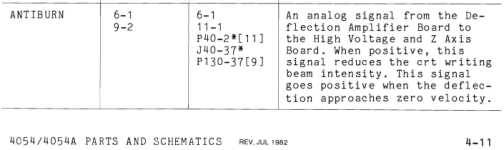

One of the calibration steps for the 4054/4054A with Option 31 bicolor DVST is to adjust CRT BIAS on the High Voltage & Z-Axis board for Option 31 display to eliminate the dot below the blinking cursor.

Here are the instructions for that step:

I was unable to get the spot below the blinking cursor to disappear in Step 6 - and the spot was visible in Step 5 on all positions of the CRT BIAS pot.

In addition - if I stopping typing or moving the cursor for two minutes - the bright orange spot in the middle of the screen appeared - and no adjustment of CRT BIAS affected that spot.

If I pressed the SHIFT key - or any other key the middle orange bright spot disappeared and the cursor appeared.

If I held down any key so it auto repeated - I observed no dot below the cursor until characters were printed near the middle, then the dot disappeared on the right side of the screen, just like the Checksum test photo above.

I have run the Diagnostic ROM Pack on the System ROM, long system memory test, Option 30 Dynamic Graphics memory test - all with no errors.

I have reseated the ribbon cables on both ends connected to the Option 30 board from the I/O board, Vector board and Display board with no change in symptoms.

I have now disconnected the Option 30 board and recabled back to the standard 4054 cabling - and still no change in symptoms.

I now believe I have a hardware issue in the CRT BIAS circuit - as this is the only mention in the calibration procedures of "dot appears in one corner of the cursor".

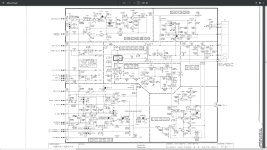

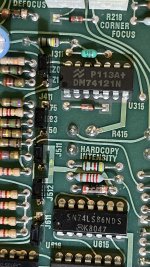

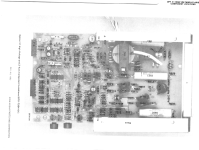

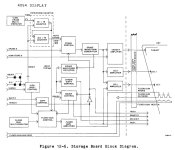

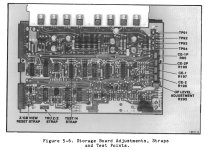

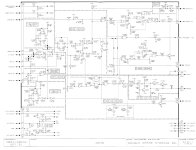

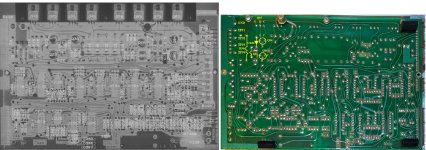

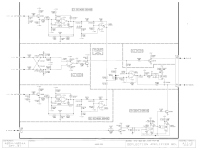

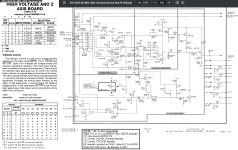

Here is the service manual page for the High Voltage & Z-Axis board for Option 31:

CRT BIAS pot is in the bottom right corner in the Z Axis Amplifier section.

The pot slider is connected to the CRT Control Grid. Note that TP778 is the high voltage output of this board to the CRT Anode.

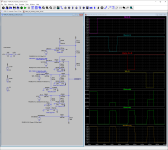

Here is the High Voltage Check at the beginning of the 4054 Calibration. I have NOT performed this test as I don't have a high voltage probe for my Fluke meter.

Note Step 5 below says if the high voltage is NOT between -5700V and -6300V you will have difficulty in making the Display Adjustments!

The High Voltage and Z-Axis power supply has a metal cover over the high voltage section - but there is a hole in the top of the cover and I can see the TP778 test point inside the cover.

I have ordered a Fluke 80K-40 probe to test the high voltage.

One symptom of the issue is a bright orange spot in the center of the screen after two minutes of inactivity in the program or keyboard as shown in the next picture:

The bright orange spot is two lines above the Diagnostic ROM text.

A second symptom is the series of dots visible under each of the text characters in the middle of the screen - but not visible on the far left and far right sides.

You might notice my Checksum test reporting U845 and U863 CRC Errors - please ignore those messages. When I rechecked the Tektronix CRCs listed in the Diagnostic ROM Pack - U845 and U863 do NOT have CRCs reported on any of the BASIC ROM versions through version 5.1, nor the A-Series version 1.3 and 1.4. I believe I need to remove those two tests as the Diagnostic ROM Pack is bank-switched into the same address 0000-3FFF ROM space as the U845 ROM and therefore cannot actually access the U845 ROM Pack when the CALL "CRC" is being executed.

I spent the last two days with my 4054A top cover removed - performing the 4054 service manual calibration test procedure with the calibration programs published in my latest Flash Drive update.

One of the calibration steps for the 4054/4054A with Option 31 bicolor DVST is to adjust CRT BIAS on the High Voltage & Z-Axis board for Option 31 display to eliminate the dot below the blinking cursor.

Here are the instructions for that step:

I was unable to get the spot below the blinking cursor to disappear in Step 6 - and the spot was visible in Step 5 on all positions of the CRT BIAS pot.

In addition - if I stopping typing or moving the cursor for two minutes - the bright orange spot in the middle of the screen appeared - and no adjustment of CRT BIAS affected that spot.

If I pressed the SHIFT key - or any other key the middle orange bright spot disappeared and the cursor appeared.

If I held down any key so it auto repeated - I observed no dot below the cursor until characters were printed near the middle, then the dot disappeared on the right side of the screen, just like the Checksum test photo above.

I have run the Diagnostic ROM Pack on the System ROM, long system memory test, Option 30 Dynamic Graphics memory test - all with no errors.

I have reseated the ribbon cables on both ends connected to the Option 30 board from the I/O board, Vector board and Display board with no change in symptoms.

I have now disconnected the Option 30 board and recabled back to the standard 4054 cabling - and still no change in symptoms.

I now believe I have a hardware issue in the CRT BIAS circuit - as this is the only mention in the calibration procedures of "dot appears in one corner of the cursor".

Here is the service manual page for the High Voltage & Z-Axis board for Option 31:

CRT BIAS pot is in the bottom right corner in the Z Axis Amplifier section.

The pot slider is connected to the CRT Control Grid. Note that TP778 is the high voltage output of this board to the CRT Anode.

Here is the High Voltage Check at the beginning of the 4054 Calibration. I have NOT performed this test as I don't have a high voltage probe for my Fluke meter.

Note Step 5 below says if the high voltage is NOT between -5700V and -6300V you will have difficulty in making the Display Adjustments!

The High Voltage and Z-Axis power supply has a metal cover over the high voltage section - but there is a hole in the top of the cover and I can see the TP778 test point inside the cover.

I have ordered a Fluke 80K-40 probe to test the high voltage.

Attachments

Last edited: