jmdhuse

Experienced Member

Hello All,

Not too long ago I picked up a VT101 monitor for $100... it was unknown if it worked, but if it didn't I wasn't out too much. It did not have a keyboard, so my first step in getting it together was to build an interface that would convert a PS/2 keyboard to the VT100 keyboard interface. I have this working, although the firmware still needs work.

The monitor is the real question - I can use the brightness, height, and vertical linearity pots to adjust the display position, but on the whole it is so out focus you can't make out anything on the screen. When I press the SETUP key repeatedly, I can see something changing at the top and bottom of the screen, but it is not readable. I'm pretty confident that the logic board is operational because I have verified that communications works properly and I can hook an external monitor to the video out BNC connector and see a correct display.

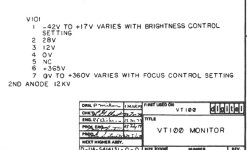

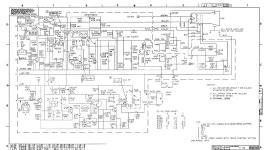

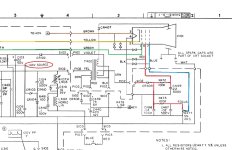

The power supply generates all the proper voltages, although the board near the chain of Zener diodes that creates -23V for the options NVRAM shows some heat discoloration. The main symptoms I have discovered are 1) the focus pot has no visible effect on the screen, and 2) the voltages at the tube are higher than the notes on the schematic indicate. The CRT board I have matches the schematic in the VT100 print set (MP00633), which indicate that the red connection to the tube should be +365V and the range for the blue connection (focus) should be 0V to +360V. On my board, the red connection voltage is +413V and the focus range is 0V to +402V. Are these higher than expected voltages a problem? I see that they are generated by secondary windings on the flyback transformer, so it seems strange that they are so different than what is spec'd.

I don't have much experience with CRTs, so I'm interested in any help or hints on how to go about this.

Thanks and cheers, Jon.

Not too long ago I picked up a VT101 monitor for $100... it was unknown if it worked, but if it didn't I wasn't out too much. It did not have a keyboard, so my first step in getting it together was to build an interface that would convert a PS/2 keyboard to the VT100 keyboard interface. I have this working, although the firmware still needs work.

The monitor is the real question - I can use the brightness, height, and vertical linearity pots to adjust the display position, but on the whole it is so out focus you can't make out anything on the screen. When I press the SETUP key repeatedly, I can see something changing at the top and bottom of the screen, but it is not readable. I'm pretty confident that the logic board is operational because I have verified that communications works properly and I can hook an external monitor to the video out BNC connector and see a correct display.

The power supply generates all the proper voltages, although the board near the chain of Zener diodes that creates -23V for the options NVRAM shows some heat discoloration. The main symptoms I have discovered are 1) the focus pot has no visible effect on the screen, and 2) the voltages at the tube are higher than the notes on the schematic indicate. The CRT board I have matches the schematic in the VT100 print set (MP00633), which indicate that the red connection to the tube should be +365V and the range for the blue connection (focus) should be 0V to +360V. On my board, the red connection voltage is +413V and the focus range is 0V to +402V. Are these higher than expected voltages a problem? I see that they are generated by secondary windings on the flyback transformer, so it seems strange that they are so different than what is spec'd.

I don't have much experience with CRTs, so I'm interested in any help or hints on how to go about this.

Thanks and cheers, Jon.