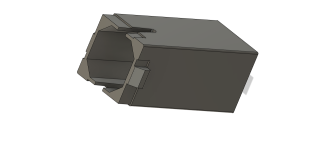

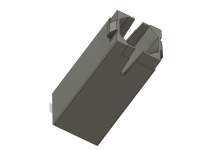

I finally got around to getting everything together to try these out. They definitely seem to fit in every Hi-Tek keyboard I tried, but they were a bit hard to put in, probably because they don't have as many cuts in the side to relieve the pressure. That last push sometimes wouldn't work, then I would push again a minute later with success. Once fully pushed in, they work and feel just like the originals, except that your key caps don't fall out. Note that the cuts on the hook side have rotational symmetry, so the plungers are identical if you rotate them 180 degrees. There's also sometimes two dots of flash on one side of the replacements, but that should shave off with a razor blade. You can see it on the first one in the second picture.

I realized that my usual method of pulling them out with needle-nose pliers could break the little edge at the top of this design, but it's not really a problem because you shouldn't need to pull them back out again unless they break, just be careful. Sometimes one edge didn't print well, giving a side to pull on, but even if you break the middle of an edge, its purpose is to reinforce the corners, so not all that bad.

Anyhow, the "usual rules" for replacing plungers successfully still apply, some of which I had to re-learn:

- Don't use a screwdriver or other object as a lever to pop off the key caps, as that could put stress on the plunger corners and make them worse. Use a proper wire key cap puller instead. If they easily come off on their own with just your fingers, that should be okay, but that means a corner may already be broken.

- Make sure the bar is in the right direction, but you can also tell the orientation by the hooks on the bottom.

- When pushting the plungers in, stop just before you reach the metal fingers to make sure that they line up. Sometimes they're a little off and won't separate around the bar properly, and you could squish the metal fingers. If you don't mess them up first, you should be able to nudge the metal fingers over just enough to center them. Replacing the fingers (assuming you even have donor parts) is much harder.

You shouldn't need to replace every plunger, just the ones giving you trouble. The main troubles are sticky keys and key caps that fall out too easily.

And these won't replace the plunger of a mechanical caps lock key. I noticed that it has a special plunger with one of those clicky pen mechanisms, but no way was I going to take it apart with the chance that I couldn't put it together again. Fortunately the one I looked at did not have its corner split.

deskthority.net

deskthority.net