wootwootman

Member

- Joined

- Dec 10, 2024

- Messages

- 15

I recently inherited three Vectrex consoles in various states of (dis)repair from a family friend, and I'm dead-set on trying to get at least one of them up and running. The one shown in the attached pic is probably the one closest to running properly so I wanted to try and tackle it first.

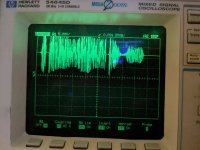

After opening the case on this particular unit, I was surprised at the lack of dust, which led me to believe that the unit had been re-capped recently. Looking at the integrator caps seemed to confirm this, as they appear to be the red rectangular caps as opposed to the older silver cylinders. Upon powering on with the test cart installed, the grid appears wavy as seen in the pic, and does not appear to move around. Also, I haven't been around a Vectrex in many years, but I believe it may be buzzing a little louder than usual.

If anyone has some tips or is willing to help out, let me know. I have a multimeter, oscilloscope, and entry-level soldering station so I should be able to at least take measurements and swap/repair components as needed.

Edit: I have found a previous Vectrex related thread where Dave provides extraordinary assistance. I'll go ahead and get the service manual to start working through the troubleshooting guide.

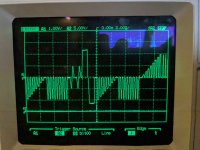

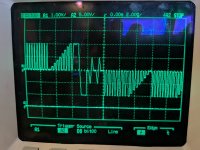

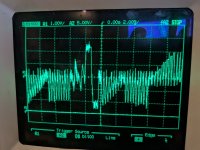

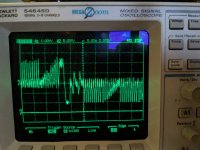

Would connecting my scope to the two axes in XY mode possibly show a rough estimate of the CRT display? Maybe I can use that to track the signal through the analog side, though I suspect it may be a larger issue, since it seems both axes are affected

After opening the case on this particular unit, I was surprised at the lack of dust, which led me to believe that the unit had been re-capped recently. Looking at the integrator caps seemed to confirm this, as they appear to be the red rectangular caps as opposed to the older silver cylinders. Upon powering on with the test cart installed, the grid appears wavy as seen in the pic, and does not appear to move around. Also, I haven't been around a Vectrex in many years, but I believe it may be buzzing a little louder than usual.

If anyone has some tips or is willing to help out, let me know. I have a multimeter, oscilloscope, and entry-level soldering station so I should be able to at least take measurements and swap/repair components as needed.

Edit: I have found a previous Vectrex related thread where Dave provides extraordinary assistance. I'll go ahead and get the service manual to start working through the troubleshooting guide.

Would connecting my scope to the two axes in XY mode possibly show a rough estimate of the CRT display? Maybe I can use that to track the signal through the analog side, though I suspect it may be a larger issue, since it seems both axes are affected

Last edited: