I finally got the keycaps in!

Bear in mind that the basic keycap set has to be a good fit for several different machines, and therefore won't be an exact match to the Sol. The Sol-specific add-on keyset matches the basic set. These keys are less glossy than the Sol keys, more of a satin finish. I ordered "deep dish" F and J keys for homing, but once I have them I see that the "deep dish" keycaps are closer to the original key shape. The rest of the keys with the normal SA shape are slightly shallower. But the keys are look and feel great, and are high quality double-shot keys (except for the keys with LED lenses, which had to use dye-sublimation printing since the window uses the double-shot process).

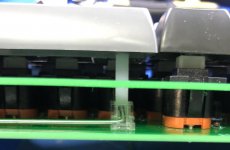

I added the keycaps on my keyboard, and took some photos:

My lab is washed in LED lighting, so the pics don't capture the LED lights very well, but they do look good, and that's without trying to optimize the LED installation. I think the LEDs will benefit from mounting a little higher off the board and bending them inward at the level of the aligner.

The fit is overall pretty good. The keyboard I have is one rev behind the latest. The latest rev moves the slots slightly to better position the keyboard within the cutout, and also adds some mounting holes on the right side of the keyboard, to allow mounting the encoder board so it doesn't bump into the main board. I have some of the new revs, but was too eager to try out the keycaps to build a new board up. In fact, I may just keep what I have and do some drilling and filing instead.

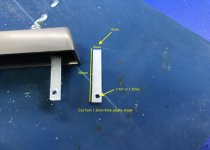

I think the futaba keys are not too far off the feel of the original, and they're cheap, so I used futabas in this build. I believe I have a solution to use the cherry stabilizers for the futaba keys, and will post the stabilizer results soon.

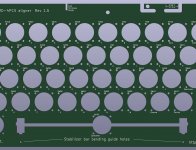

I did notice some errors, seen in the photo below:

There may be more, but what I noticed is that:

1) The RETURN key is gray, but should be black. I believe this is a factory mistake, and hopefully they will correct it.

2) I forgot to order a DEL/_ key. You can see I fitted a RUBOUT key from the basic keyset, but I will probably go ahead and order the DEL key for completeness.

3) I specified the keyboard decimal character as a period ("."), and it's not centered in the key. That's my fault. I'm not sure if I'm OCD enough to order a replacement, though.

Anyway, as far replacing the missing keyboard for my "unibody" Sol, I think I'm set. If anyone is interested in building one up, I have quite a number of keysets available.

Dave