So now that I am resigned to making my own control panel for my H200 replica I have made a very modest start on that, most of my time having been in demand elsewhere. Fortunately my ex Honeywell field engineer friend, having recovered from his seriously shattered leg injury, got into his loft and found there an original control panel fascia, so he created from this a full size template showing where all the holes for the buttons are. This ensures that my panel will be an accurate replica regarding the exact positions of the buttons.

However, this fascia was clearly from a later machine in the H200 series as the earliest design H200, such as the one in the previously mentioned film

Billion Dollar Brain had a slightly different layout. This template corresponds to the

H120 panel in the Rhode Island Computer Museum but the same layout was used for all later machines in the H200 series such as the 1200 and 2200. My own website

https://honeypi.org.uk/ shows a CGI representation the original H200 panel which I intend to build. One evident difference in it is the use of a single toggling Address Mode button to switch between modes 2 and 3 whereas later machines used individual buttons to switch to modes 2, 3 and 4 according to the capabilities of particular machines. However, a more subtle difference is the position of the buttons at the right of the panel. On the original machine as on my website the sense switch buttons were in line with all the other buttons on the bottom row and the Display/Enter buttons above were logically placed halfway between the rows of buttons to which they referred. In contrast on the template above and the RICM H120 panel the sense switch buttons have been moved a third of a row down and the display/enter buttons a third of a row up. This was done to provide space for a second row of sense switches on some machines and the modification then appears to have been applied on all subsequent panels including the more basic H200 according to the assembly schematic.

An extremely subtle change in the control panel was that the button originally labelled "Central Clear" as on my website was later relabelled "System Clear". This was no doubt done to make it clear (!) that the button actually affected all the peripheral devices in the system rather than the CPU as the only thing that could be regarded as "central" in this respect was the control panel itself within the system! When I was working on the H200 back in the 1960s I never understood why that button was labelled "Central Clear" and evidently nobody else did either so it was renamed, but my replica must remain faithful to that early era.

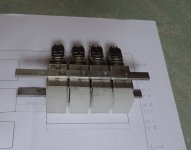

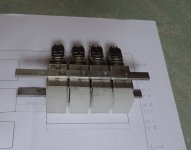

Regarding physical construction of the panel, my collection of switches came from several donors with the result that I have three different types of fitting on them in equal numbers. Some switches have side clips, some top and bottom clips and some brackets, so I can't use them all together as they are in any consistent fashion. However, they all have the same rivet holes in their casings where these assorted fittings are attached, so if I remove all the fittings entirely I can just mount all the switches with screws through the rivet holes. I have made up a small block of switches on some steel bars I had to hand in this way and there are no problems with the screws fouling the internal components of the switches, so I intend to make the whole "panel" this way although no actual panel will be needed apart from the dress fascia panel just to enclose the switches rather than support them. This approach will also allow me to assemble and wire up each row of switches individually, which will be easier than making a single large panel and mounting them all on it to be wired up there. This project is after all just a pastime for me and I always want it to be as easy as possible just to retain my sanity. The trial block of switches is shown below.

Unfortunately just the other day while I was machining the essential chamfers on the integral edge connectors of some new PCBs manufactured for the project the motor control electronics of my milling machine died, so I am now having to diagnose and fix the problem with that as without the milling machine I can't drill the holes in more steel bars to position the control panel switches precisely enough to match the template exactly . Ah well, one step forward two steps back again ...