Unless you have a scanning electron microscope, you can't be sure there are no cracks in the joints, because they can be microscopic, but cause problems all the same. The goal is to make sure there are no phantom faults caused by microscopic cracks that can change literally by bumping the table the machine is sitting on, or even by thermal cycling. Every single analog board I've ever worked on has had cracked and dry solder joints that have caused real problems.

These failures are notorious in all Compact Macs due to the heat and having extremely poor ventilation. It's LITERALLY the first step you should do when working on any analog board, even of known origin, because of all of the heat stress. Telling someone not to do it is just terrible advice and will needlessly complicate and extend the potential repair time.

An easy and not so scientific test is to take a plastic implement and tap the back of the analog board moderately while the machine is running. If you see any glitching on the screen, or voltages start to change, there's a bad joint somewhere on the board. It could be a connector, it could be a component.

Well that maybe so, and it is a reasonable idea to slightly flex the board too, but like I said, I inspect the soldering, and would re-solder any obviously broken or suspicious looking connections.

But, initially at least, I never do it globally across a whole board (nor do a global re-cap for that matter either).

The reason is that some components can have thermally related failures. When you heat their solder joints up it heats the components too, it can cause the fault to clear. Then if the fault does not come back immediately, it can appear days weeks or months later. I have seen this quite a few times, a technician re-flows the whole board in desperation, suddenly everything starts working and it goes back to the customer, a week later it is back in the shop with the same fault.

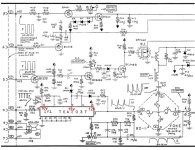

I prefer to analyse the circuit with scope tests, and if that leads to the fact that one or more of the solder joins is open circuit, but looks physically normal, I find it that way. Generally though, with through hole boards, it is pretty easy to spot the 360 degree ring fractures that appear in the solder around the lead wires, good light and magnification help, I have never had to bother with an electron microscope !

But as I said, I prefer this method myself, to be 100% sure I have found the exact fault that is causing the presenting problem. But I'm not saying that everyone else should subscribe to it.

There is also something else:

The notion of "notorious failures" in certain models.

There was once a school of thought, that if every model had its common failures documented, it would create a database that a technician could use, to repair that model.

This idea was based on the concept that it might save workshop time and that a technician with limited diagnostic skills and understanding of circuit theory could end up fixing most sets.

This may well have been true, for "most" sets.

It is a probability method which relies more on the completeness of the "common fault data base for the model", than the knowledge, experience and diagnostic skill of the technician. This is somewhat analogous to fault finding flow charts. Which an experienced technician knows are not worth the paper they are written on.

This is because not all broken appliances that end up on your desk are "Most" machines, the bulk of them might be, but sooner or later, the technician who uses this system will be presented with a fault or problem that is unique, nobody has seen it before, or documented it, and they will be helpless unless they apply better diagnostic methods.

A better method for repairs relies on test data and an understanding of how the circuit works, to formulate a theory on where the fault resides, to lead to the exact fault, regardless of how common it might be, or not.

Though even this system is not 100% perfect either. One thing that allows a technician to find the fault, is the circuit design itself. Because for any presenting problem (not talking about dead circuitry here but malfunctioning circuitry) there are only a certain number of things that can go wrong with a specific design. However, when Tin whiskers turn up, these can connect unrelated sub-circuits together, to create a new circuit. The faults can be bizarre and not conform to expected patterns. So one major clue; is when two sub-systems appear to be interacting in an unusual manner, and common power supply issues are ruled out, check for whiskers.