Mike Brixius

Experienced Member

On my pet 4032 there are 3 or 4 keys, all in the lower left corner that are very unreliable. This is a Graphics Keyboard

The stems are good and work perfectly in other positions (They read about 200 ohms)

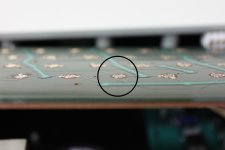

The board has continuity (I had to repair 3 of the overlay traces)

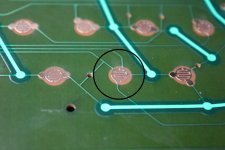

Here's the rub, the pads look perfect and if I hold a stem and press on the board pads it reads great except on these pads. In their cases I have to press the pad a little lower than centered or it doesn't read. I am guessing (I know) that the traces for one side of the circuit are a little thicker than the other preventing contact?

All the problem pads are ion the lower left centered on the C key which is the worst

I dunno it is VERY weird. Ive thought of tinning the contact trace where the pad contacts but there is no going back from that.

Mike

The stems are good and work perfectly in other positions (They read about 200 ohms)

The board has continuity (I had to repair 3 of the overlay traces)

Here's the rub, the pads look perfect and if I hold a stem and press on the board pads it reads great except on these pads. In their cases I have to press the pad a little lower than centered or it doesn't read. I am guessing (I know) that the traces for one side of the circuit are a little thicker than the other preventing contact?

All the problem pads are ion the lower left centered on the C key which is the worst

I dunno it is VERY weird. Ive thought of tinning the contact trace where the pad contacts but there is no going back from that.

Mike