Hugo Holden

Veteran Member

Yes, just not quite as rare as the F3342 or the TMS3417. It is quite possible that I have some of the world's remaining few specimens of these parts in my workshop. I think though there will be more of the 74HCT7731's out there, a good one to find would be the SOIC package part that were once stocked by Mouser, this more modern stock is probably about, just a matter of finding it. These would fit well on an adapter board.The same listing is on American eBay so... yeah, I guess there are 45 of these in a warehouse in Israel. That doesn't really negate the point that it's a really hard to find part.

It looks like the rare TMS3417 problem has "gone away", for now at least. Interestingly the TMS3417, 1979 date code, & ceramic package, is now available on ebay and plenty available by the look of it, anyone with an original Dazzler or planning to make my replica should stock up:

TMS3417JDC (X2) RARE VINTAGE TEXAS PMOS DYNAMIC SHIFT REGISTER IC CERAMIC DIL | eBay

2 X TMS3417JDC. LEGS ARE TARNISHED BUT WITH A CLEAN THESE PARTS SHOULD FUNCTION OK.

www.ebay.com

There was a mention, even in the 1970's that the TMS3417 was hard to get, they must have had a very limited production run. They had the vintage TI package made of very hard resin, cut off at each end with a cutting tool and pins that were perforated with a hole as the enter the IC package. I have seen that before on some if TI's early resin package IC's.

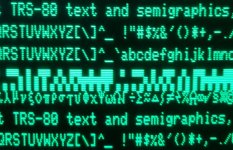

The other interesting thing about the Dazzler color encoder; they provided phase adjustments for green and red, but not blue. Blue was derived from a near exactly phase reversed burst. Because of this, the color image out of the Dazzler cannot produce a pure blue, it generates a "purplish looking blue" as there is a phase shift for the blue carrier toward magenta .You can see this looking at the still frames of the Kaleidoscope images. That is quite a "unique look" too and no doubt would have escaped the attention of the Dazzler replica output, which would likely be perfect RGB color. Again though, is that a quirk to admire or a problem to be fixed ? I'm not so sure, but I cannot help admire the way they pulled off their color encoder with a few logic gates and some L-C circuits. I've never seen that done elsewhere, generally the designer reaches for a standard color IC for composite video to do it.

Last edited: