Well, I went ahead and did a build of 10 SMT protos thru JLCPCB. I wanted to source all the parts thru them (makes the assembly process go smoothly) and not have to do any rework myself.

So I could not find a suitable low current 2ma LEDs and had to go with standard 20ma devices, so I added 2N7002 driver transistors for each of the three display leds. Not a big deal.

For the 5V/3.3V 4bit bidirectional translator TXB0104 I used, they did not have the SOIC14 package in stock, but I had to substitute a TSSOP14 instead.

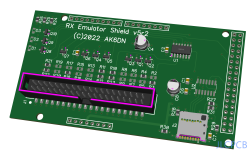

So after the UPS box arrived today, I unpacked and soldered on the thru-hole Arduino headers (now 2x8P, 1x10P, 1x36P). This is the only hand assembly required.

I think I could have had that done by JLCPCB also, but I was using the one-sided basic SMT process and did not want to perturb that flow. So some hand assembly required, about 5min of work.

And the board works, 100% compatible with the existing Arduino code and the microSD card. Just swapped out an old thru-hole v4 board on my 11/44 setup with this new v5 board,

swapped the microSD card in, powered up, and off to the races. Ran the basic DEC RX02 diagnostics (ZRXFB0 logic test, ZRXDC0 data exerciser) and they both fully passed, same as old v4 version.

Will run it on my PDP-8m RX8E/28 later this week, but I don't expect to see any different behavior.

Overall I was very happy with the working with JLCPCB. I had built bare boards with them before, so no change there. Quantity 10 of this 55x100mm 4 layer board cost just $2 each.

Surface finish leaded HASL, if you want ENIG gold it has a adder.

Overall total cost to me per board (PCB fab + parts cost + assembly cost + UPS shipping) was about $12.50 each. Much lower than I thought it was going to be. I was expecting about twice that.

JLCPCB has an extensive inventory parts library and their cost per device is usually 1/4 to 1/3 that of buying small quantities of parts from Mouser, DigiKey etc.

Anyway they did an excellent job overall (PCB fab in 4 days, assembly in 2 days) for a build of 10 boards. I used UPS shipping this time vs DHL other times. Same cost but arrived in half the time (3 days).

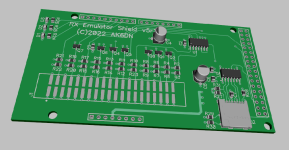

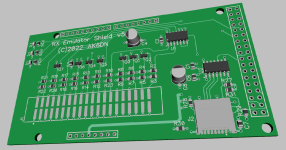

Here is a picture of the board (headers not yet attached on the backside) as delivered from JLCPCB: