Thanks Dave, I was confused about the missing letters in the alphabet, and went for the 'K' on the connector. Maybe someone here knows why those edge connectors are missing some letters?

The BOM for the debug board is in 'DBGBD.TXT' of the above blog post.

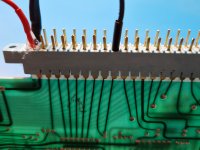

I found these connectors:

View attachment 1281933

The 'type B' connector with the little holes should be better for soldering directly to the PCB edge connector, no?

I'll be back in few weeks when I have the board assembled and programmed

Bend the pins down to the board, don't expect to hold the terminal down to the board with solder to hold it to the board and tension, between the pin and board. The connector solder side should naturally hold against the board or at most have a small solder filled gap. Solder is not a solid connection, it is just a electrical connection.

Also make sure the connector slides onto the KIM's connector before soldering to the diagnostic board. I found the several connectors with the correct pin spacing will not fit the KIM board and a little additional opening of the connector ends. I did this with a bur tool on my Dremel tool.

You do have to remove the end connector pins as they will be easily damaged,working so close to them.

They relatively easily push out by needle nosed pliers on the solder side. You should only need to remove the two nearest each end when you are expanding the end opening of the connector socket. I suppose it might be possible to use a small end mill bit with a vice to hold it and a drill press or mill. If you wanted to I suspect you could remove more pins, as far as the blade will go, and use a narrow saw blade. Once it is enlarged you could glue a small piece to fill in where too much was removed. The blade needs to be wide enough to let the KIM board to clear.

There is a little trick to putting the pins back in. If you just try to push them back in, without a little help from a "special" tool, you will bend and damage them.

What I find works as a good special tool is a credit card slid to the pc board slot of the connector then push the sockets connector back in. The credit card ( special tool ) is the right thickness to keep from bending the spring part of the connector piece while sliding it back in place. I find the once it is part way in, I can then use the needle nose pliers to pull them the rest of the way from the solder side.

Of course, if the connector fits the KIM fine, you can ignore the end expanding tricks. I don't know why they had the reduced connectors, it is just what I found.

There is a position on the diagnostic board for normal operation of the KIM so you don't need to remove it for normal operation. In the ROM, each test code only need a small amount of memory. Most all the test have additional space in the EPROM. I put two of Butterworth's programs in the empty spaces of the ROM. I forget where but there is a "Master Mind" and an Astroids game. I like the Astroids one the most. They do have to be relocated to the empty space in the EPROM space that is selected to run. I just hand relocated his programs as they were quite small. Of course, one could reassemble other ones in other locations. The switches put a 1K part of the EPROM in memory, at 0E000h as I recall there is always a small boot vector at the end of each test section. These are only active it the test boots from the EPROM by the switch selection. If not selected to boot, one can run anything in the 1K that the switches select, like the games I put in there

Dwight