eeproks

Experienced Member

I really need to get my 11/23+ running again...

| VCF West | Aug 01 - 02 2025, | CHM, Mountain View, CA |

| VCF Midwest | Sep 13 - 14 2025, | Schaumburg, IL |

| VCF Montreal | Jan 24 - 25, 2026, | RMC Saint Jean, Montreal, Canada |

| VCF SoCal | Feb 14 - 15, 2026, | Hotel Fera, Orange CA |

| VCF Southwest | May 29 - 31, 2026, | Westin Dallas Fort Worth Airport |

| VCF Southeast | June, 2026 | Atlanta, GA |

I have done repairs on a bunch of the KDF11-B CPUs... It might not be the UARTS, but the transceivers that convert the logic RXD and TXD signals to RS-232 signals levels. Check the TXD of the actual UART (6402 pin 25) to see if the UARTs are actually transmitting data. Check for +/-12V at the transceivers.So after spending time reforming the CPU box power supply, and burning it in for several day, I finally did a smoke test of the CPU board and 256k memory.

The diagnostic lights (image attached) show "off - Power - on - off - off", according to the manual (EK-245AA-MG-001, table 3-1) means the basic system diags passed. But I cannot get anything from the console. I've verified my cabling a dozen times, and checked the default switches and jumpers (figure 1-1 and table 1-3 in the same manual). A scope on the console pins show no activity. This weekend, I plan to build a franken-cable, just three loose wires (tx, rx, gnd) that I can run and visually verify, but I wager I won't get any different results.

I notice that the power LED on the diagnostic LEDs seemed a bit dim, so out of curiosity, I checked the 5v rail, and it measures a steady 4.9v. Not sure if that is too low or what.

So currently stalled, not sure what to do. I recall reading "somewhere" about calibrating the H7861 power supply, but now I can't find the info. The other possibility is the UARTS. Sadly they're not socketed, and I really dread the idea of using a desoldering station on this thing.

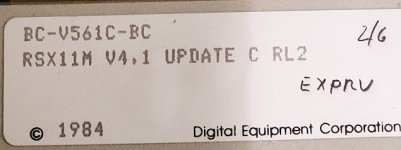

View attachment 1285635

Or use an oscilloscope to work out the real cause of the problem. If it is just a quartz/crystal or more likely oscillator that is easy to source and replace.I have a board with similar symptoms. The tests pass, but the ODT is silent. It turned out that the SLUTs do not work. Apparently, the quartz is damaged, since initially the board had jumpers - take the external clock frequency. If you install a board that plays the role of an external console SLГT - you can communicate with the board.

True... and if it is the UART or the driver/receivers, they can be found as well.Or use an oscilloscope to work out the real cause of the problem. If it is just a quartz/crystal or more likely oscillator that is easy to source and replace.

I always assume that the devices that a user can connect directly to are the most likely to be damaged by improper use...A scope on the console UART (E129) at pin 25 shows a brief burst of activity. I see the same burst on the console buffer input (E118 pin 3).

I see no corresponding activity on the output of the buffer (pin 6). I need to learn to use the storage feature of my scope, Just In Case.

I do see +12v on the buffer at pin 8 and -12v on pin 5, so the voltage looks correct. The baud rate crystal is on J20/J21, and that looks good.

I guess the first order of business is to replace the serial buffer. Are these known to fail? And is there a source for replacement? The prints only identify it as "9636", the stamp on the device says "UA9636ATC"

Some can even be damaged by proper use....I always assume that the devices that a user can connect directly to are the most likely to be damaged by improper use...

Wear nitrile gloves while doing the cleaning, unless you want really dry skin. 99% will strip the oils off your skin just as well as it will clean packs.You can order the 99% isopropyl alcohol and lint-free Kimwipes off McMaster, should be there next day anywhere in NJ. It really does need to be 99%, drugstore 91% has too much water in it and will leave residue, which increases the chances of a head crash. You must use a lint-free wiper like Kimwipes or Alpha Wipes or something, paper towels will positively not do!

Wear nitrile gloves while doing the cleaning, unless you want really dry skin. 99% will strip the oils off your skin just as well as it will clean packs.

Do clean the four "velocity tubes" behind the front panel, and look for glue / seal disintegration where the ends of the tubes come out in the front.

For sealing/resealing engine parts, I'd use some flavor of RTV silicone. But they tend to release acidic vapor when curing and afterwards whereas aquarium glue does not. Anything here to be concerned about when choosing what to use to reseal those tubes?Wear nitrile gloves while doing the cleaning, unless you want really dry skin. 99% will strip the oils off your skin just as well as it will clean packs.

Do clean the four "velocity tubes" behind the front panel, and look for glue / seal disintegration where the ends of the tubes come out in the front.