gottjoe

Member

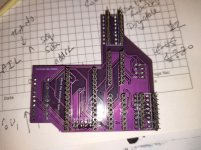

A few days ago I built a DRAM Arduino 4164 & 41256 Memory Chip Tester (it works!), and a PLA20V8 Commodore 64 PLA Replacement solution. Both projects required header pins. I used 2.54mm for both. They work great for the Arduino connection (which is what they are designed for), but somewhat damage the sockets on a Commodore 64 for the PLA replacement. I had to crimp the original PLA chip pins inward to get the chip to make contact with the socket after I tested the PLA20V8 solution (which works great). I want to build more PLA20V8's, but I need a better header pin size. Please provide recommendations for something that has worked for you.

Any help is appreciated.

Joe

Any help is appreciated.

Joe