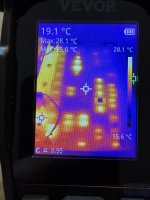

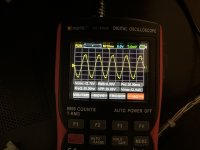

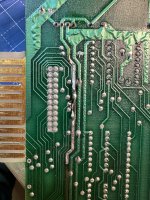

Dear all, in the process of trying to repair a PET, I had a smoke development and FI / RCD breaker tripping event. The suspected RIFA that burned was removed but the PET would still not run just like before. This was followed by a solder trace burnout on the back of the PCB (one of the power rails). I repaired the trace and suspected something wrong in the power supply. I also measured around the rectifiers and what not but came to no conclusion. So I went to try the bridged PCB in one of my working PETs (bad idea). Well, then I had a power supply smoke event with additional FI / RCD entertainment and damage to the previously working PET. Plus, I felt slightly sad and not so smart afterwards. Interestingly, despite the smoke and FI / RCD, the previously working PET is still working but has suspicious power draw even when off. And here are my questions for you experts:

- How much power usage is to be expected when the PET if off? (Mine now draws around 1W. I guess from the RIFA and that seems wrong.)

- Is it possible that a damaged mainboard destroys the RIFA?

- Any advise on how to continue my fixing procedure

- Why are almost all my PETs making this pretty loud humming sound when they are on? (Can it be ignored or is it a safety concern that needs fixing