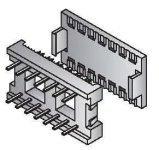

I think I got them from various ebay sellers at the time as I recall.

But, I also noticed recently that a very trusted seller, I often buy parts from him, his name is Dinos and the ebay seller ID is Qservice-electronics, has these lovely Augat sockets as they are used in Tek scopes, and he supplies parts for these.

These are the 16 pin ones, so if I were building another I'd get these:

Find many great new & used options and get the best deals for 5 PC Augat IC Socket 16 Pin DIL Gold Plated Machined Leads NEW Ref # 786567674 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

I'm not sure if he has the 14 pin ones though. It would be worth asking him, he has lots of things.

These 14 pin ones look ok if Dinos dos not have the 14 pin variants:

Find many great new & used options and get the best deals for Augat 514-ag10d 300 Mil 0.3" DIP 14 Pin Gold IC Socket Te CONNECTIVITY at the best online prices at eBay! Free shipping for many products!

www.ebay.com

One advantage of the all Gold Augat socket is that even if they are old stock the pins are not as subject to corrosion as Tin plated ones, so generally they solder very well, unlike aged Tin plated ones which can give significant trouble, so it is not as important that they be new manufacture as it is for the Tin plated ones.