Hi Dave, this evening I spent a lot of time on the vectrex, I once again cleaned the area of the operational amplifiers where there was a bit of dirt, thinking that it could generate high resistances between the pins of the components, then I rechecked the connections between them again, I also desoldered the 3 potentiometers to check their status.

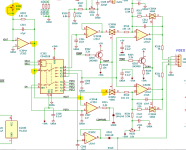

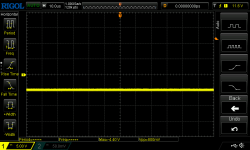

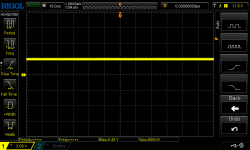

There are 2 10k potentiometers for the x y adjustments and one 2k for the dac offset. one of the two gave me a value of 11.2k unlike the other with 10.2k, I don't think it's a problem. I then tested all the chips again with old and new, I found no differences. I studied the differences between the scheme and the 3g and nobuz board, basically the 2 34001s manage the outputs of the x and y axes while the 34004 manages the z axis and something related to the dac offset. I again set the offset at 0 volts using first the oscilloscope and finally the multimeter, it is perfectly at 0v when the test image disappears. However, I noticed something very strange, before I attempted to change the integration capacitors, which I then made a mistake and was forced to reassemble the old ones, the two 10k potentiometers allowed me to adjust the image correctly, this always in the system hot , and the position of the wheel of both was almost the same, while now one of the two is at full scale and does not allow me to adjust as well as before. Seeing that everything works through the 34001 and some resistors and with the two voltages +5ana and -5ana, I checked that everything was connected according to the diagram. as connections, although different on this board, correspond to what the diagram states that they should do but I noticed that the values written in the diagram do not appear to me, that is, in the two potentiometers the diagram says that the two side pins 1 and 3 should be connected respectively to -5ana and +5ana, but with the multimeter I saw that for R335 it corresponds to what the diagram says and therefore corresponds to pins 7 and 14 of the 4066. For the other, however, this is not the case despite the diagram indicating the same thing. I then turned it on to check the voltages with the multimeter and I saw that instead on both potentiometers I have a negative voltage of -4.98v on external pins 1 and 3, I shouldn't have -5v and +5v on them as the diagram says ?

Then I checked the resistors in the circuit in this area and they are all ok.

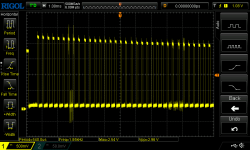

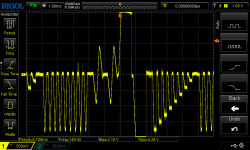

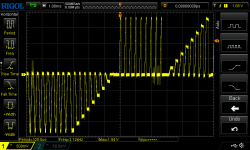

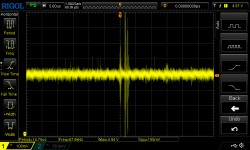

Then I connected the test cartridge again choosing test distortion 2, the one with the two squares one inside the other and I saw that I always have the left side with two vectors completely out on their own, I brought my finger closer between 34004 and 34001 of the y axis and with my finger the two vectors tend to return to their correct place, if I move my finger away they go back out of the pattern! At this point I think they could really be the integration capacitors since I changed everything in the area except them, even though they would seem good. In all this time of testing the system has warmed up very well but despite everything the adjustments cannot be made properly and in the games you can see graphic errors in the positioning of the vectors or the writings upside down, or compressed or even too enlarged.

I put in the scramble game, which seems to be pretty ok except for the fact that in the second level the upper rocks move along with the movement of the controller!

Given this, I'm starting to think that it could be a defect in the audio chip or the RAM!

I don't know where to look anymore, I'm giving up, I probably won't be able to understand the problem and will have to abandon it, the only problems I have are the 4066 which I will try to test on a Commodore64 tomorrow.

I'm really tired of taking everything apart every time and then not solving it.

At the moment there are all new components, both on analog and logical boards, except the integration capacitors, or I should remove the new sockets that I put in and check again if there is any problem underneath them.

I don't know