BlaBla1985

Experienced Member

Looking through some ebay listings I thing the mounting is not that big of a problem. It seems to be the same as some generic mono audio cassette head sold for less then 10 euro's a piece. At that price i might just buy a few and see what happens. The only issue is I don't want to damage anything inside the calculator. Would using a tapehead with the wrong impedence from it's coil damage anything on the other end?Mono tape heads are still available new.

The tricky part might be matching the mounting, as there are many variations.

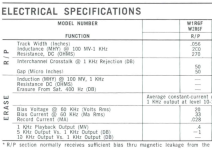

The resistance will be guesswork - usually around 100-300 ohms for cassette types, and you may need to modify the recording current 5k6 resistor for best results.

I have very little experience with tape systems, I've never used any home computer with a tape deck. I would hate to do something stupid and ruin this machine by using a cheap tape head...