BlaBla1985

Experienced Member

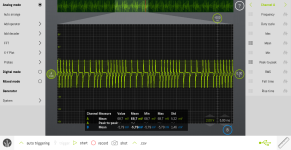

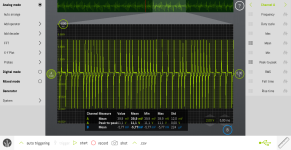

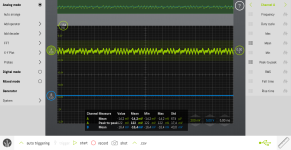

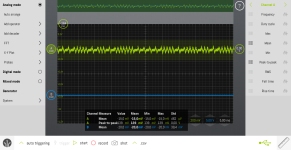

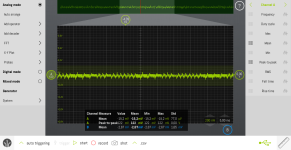

Oh, I was looking for what MHG would be in all the wrong places. I wasn't sure if connecting the groundlead of the probe to the otherside of the resistor was a good idea.Usually, a scope probe has it's own "ground", or perhaps better called the signal return. That does not mean it literally should be connected to ground, but rather that it needs to anchored to the "other side" of the circuit. That would be MHG in this case, which is the "common" connection for both MHO and WDT.

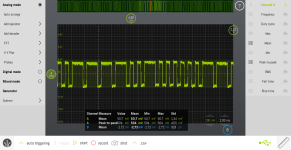

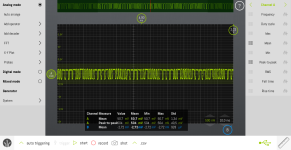

When I was working on getting the expansion pcb for the Sharp PC7100 I was indeed able to filter out most noise to get a measurment on the clock (which is a much higher frequency that this). So it can get fairly clean measurements.